preeflow® eco-SPRAY High Precision Volumetric Dosing Unit, Spray Dispensing System

About preeflow eco-SPRAY Spray Dispensing System

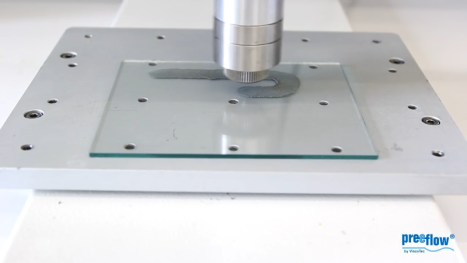

The preeflow eco-SPRAY spray dispensing system combines the reliable preeflow endless piston principle with a low-flow spray chamber, resulting in highly accurate spraying of low to high viscosity fluids with high edge definition. Based on preeflow’s proven rotor/stator dispensing technology, the eco-SPRAY provides superior process control.

This dispenser offers flexibility thanks to viscosity independence and a variable spraying pattern, as well as cost savings due to reduced waste and altogether higher process reliability than standard spraying technology.

The eco-SPRAY is capable of precisely nebulizing and spraying on either a continuous or intermittent basis. It offers a constant amount dispensed per area, uniform coating, and controllable round spray alongside technical features including defined quantity spraying, viscosity and primary pressure independent spraying and a controllable spray area.

We can integrate the preeflow eco-SPRAY into any robotic dispensing system.

Features & Benefits

Viscosity-independent spraying

Viscosity-independent spraying- Spraying of defined quantity, regardless of primary pressure

- Controllable round spray area, with little overspray and high edge definition

- Constant amount/area and consistent spray-image results in uniform coating

- High chemical resistance allows a variety of media from low to high viscosity: grease, adhesives, ink, silicones, abrasive media, highly filled media, activators/primers

- Low maintenance system which is easy to clean

Specifications

| Specification | |

|---|---|

| Dimensions | 228mm high, 35mm diameter |

| Spray accuracy | ± 1% |

| Repeat accuracy | > 99% |

| Min. spray quantity | 0.05ml |

| Volume flow | 0.5ml to 6ml per minute |

| Diameter | 0.2mm, 0.3mm, 0.5mm |

| Material infeed | 1/8″ cylindrical whitworth pipe thread DIN/ISO 228 |

| Parts with medium contact | HD-POM/Stainless Steel/PEEK |

| Min. operating pressure | 0 bar, self-levelling fluid |

| Max. operating pressure | 0 to 6 bar input pressure, non-self-levelling fluid |

| Intrinsic tightness | Approx. 2 bar (reference medium approx. 10 mPas at 20° C) |

| Seals | High-molecular PE, VisChem |

| Motor | 18 to 24 V/DC, incremental encoder, planetary gears |

| Switching frequency | Over 100 cycles/min |

| Operating conditions | +10°C to +40°C, air pressure 1 bar |

| Medium temperature | +10°C to +40°C, air pressure 1 bar |

| Medium viscosity | Low to high viscosity media |

| Atomizer air | 0.1 to 6 bar |

| Atomizer supply | Hose connector external diameter 4mm (connection to the process M5) |

| Spray image | Round spray (adjustable) |

| Spray angle | 15 to 30° |

Other Information

See also our Technical Articles and White papers page to download “The “Endless Piston” Pump – Technology for Precision Dispensing” – a whitepaper about this technology.

Ordering Information

| Part number | Description |

|---|---|

| VIS21448 | preeflow eco-SPRAY |

| VIS21499 | preeflow eco-SPRAY controller |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 2.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.