Opti-tec 5013-1 Optically Clear, Fast Cure Epoxy Adhesive for Glass and Glass/Metal Bonding

OPT 5013-1

About Opti-tec 5013-1 Optically Clear, Fast Cure Epoxy Adhesive

Also available to buy online at ![]()

Opti-tec 5013-1 is a two-component, medium viscosity epoxy with high optical clarity. It has a fast room temperature cure, which can be accelerated by heat. Opti-tec 5013-1 is designed as an adhesive, or for small potting and encapsulation projects where high optical clarity, good wetting and medium viscosity are important.

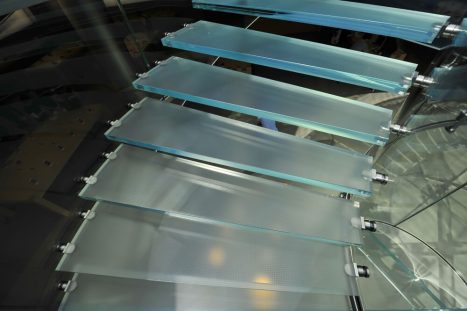

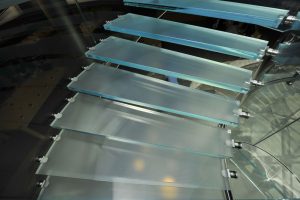

Opti-tec 5013-1 can be used for bonding glass, quartz, metal and many plastics. It finds uses in the assembly and repair of glass items where a clear adhesive is required.

Features & Benefits

- Optically clear

- Viscosity of 5,000-10,000 cps

- Sets within minutes and cures within hours at room temperature. It reaches handling strength in 30 minutes. Full cure can be achieved in 10 minutes at 65°C.

- High surface energy allows it to wet and wick between surfaces. It develops strong adhesion to most materials used in optics, including metals, ceramics, glass and most plastics.

- Good impact and thermal shock resistance

- Hard material after cure and can be polished

- Good resistance to yellowing

- Supplied in convenient side-by-side double syringe cartridges, complete with static mixing nozzles.

Applications

- Glass and metal bonding

- Repair of glass, wood, ceramic, metal

- Repair or restoration of minerals, gems and quartz crystals

- Optical assembly, optical filters, lenses, prisms

- Optical encapsulation & glob topping, small volume casting or potting

- Opto-electronics, photonics, LEDs

Specifications

Part number change: as of version 3.0, April 2021, the part number of this product changed from Opti-tec 5013 to Opti-tec 5013-1. This is due to an unavoidable change in a formulation component. This change does not affect the product data-sheet specifications. The new formulation has passed internal testing and is deemed to be equivalent.

| Typical properties | Opti-tec 5013-1 | |

|---|---|---|

| Mix ratio | 1:1 resin to hardener | |

| Mixed viscosity | 5-10 Pa.s (5,000-10,000 cps) | |

| Colour | Clear, water white | |

| Specific gravity | 1.20 | |

| Pot life | 5 minutes @ 23°C (2 gram mix) Recommended maximum application 2 grams Larger quantities may lead to exothermic reactions which may have undesired effects |

|

| Cure schedule | Bondline temperature 23°C 65°C |

Time 2 hours 10 mins |

| Cured properties (24 hours @ 23°C) |

||

| Hardness | Shore D 70 | |

| Temperature range | -60 to 125°C | |

| CTE | 55 ppm/°C | |

| Lap shear strength (Al/Al) | 8 MPa | |

| Refractive index | 1.54 | |

| Shrinkage on cure | 3% | |

| Shelf life | 12 months in original sealed containers | |

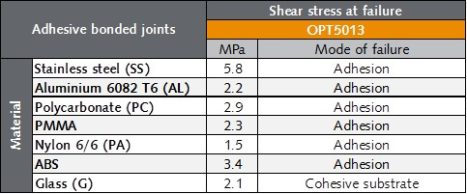

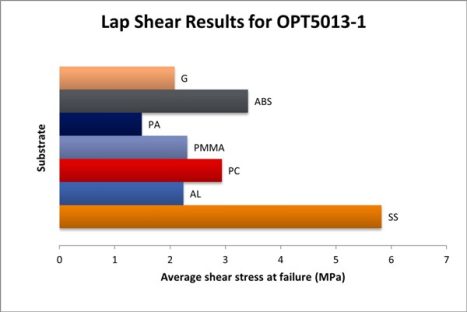

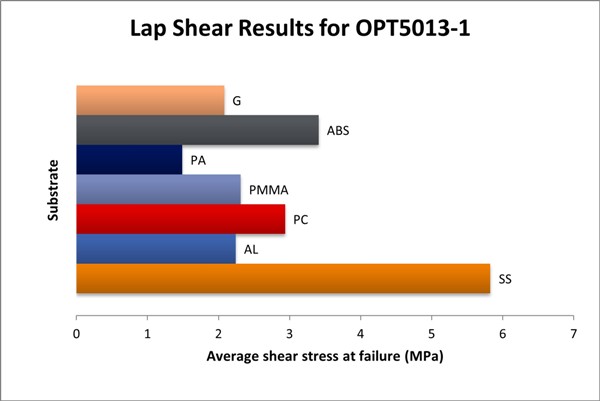

| Adhesive bonded joints | Sheer stress at failure (MPa) | Mode of failure |

|---|---|---|

| Stainless steel | 5.8 | Adhesion |

| Aluminium 6082 T6 (AL) | 2.2 | Adhesion |

| Polycarbonate (PC) | 2.9 | Adhesion |

| PMMA | 2.3 | Adhesion |

| Nylon 6/6 (PA) | 1.5 | Adhesion |

| ABS | 3.4 | Adhesion |

| Glass (G) | 2.1 | Cohesive substrate |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

|

Structural Adhesives Selector Guide

Start your adhesive selection process by reading our Structural Adhesives Selector Guide, detailing different chemistries and material specifications. |

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

Our Technical Bulletins page has links to:

See how Opti-tec 5013-1 works as part of real application in this adhesive Case Study:

|

Glass artist completes high-quality work in short timelines with Opti-tec 5013 epoxy

The award-winning glass artist, Anthony Scala, uses Opti-tec 5013 optically clear, fast-curing, glass epoxy to effectively repair sculptures without sacrificing process speed. |

Ordering Information

Opti-tec 5013-1 is available in a convenient side-by-side double syringe cartridge.

The OPT5013-1-50KIT contains a 50 gram cartridge of epoxy, a Syringe Gun and three static mixing nozzles. It is ideal for product evaluations or small quantity users.

| Part number | Description |

|---|---|

| OPT5013-1-50G |

Optically Clear Fast Cure Epoxy Adhesive, Double Syringe Cartridge, 50g |

| IDM805001 | Syringe Gun – for 50g cartridges |

| IDM2N10 | Static Mixing Nozzle (pkg 10) – for 50g cartridges |

| OPT5013-1-50KIT |

Contains 50g cartridge of epoxy, a Syringe Gun and three static mixing nozzles |

Storage: Store in the original unopened containers under cool dry conditions between 15° and 25°C.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 3.3

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.