Microdispensing Jetting Valve for all viscosities

VER 1014617

About Microdispensing Jetting Valve for all viscosities

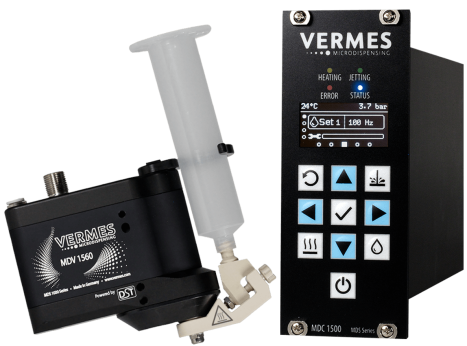

The Vermes Microdispensing System MDS 1560 dispenses material in small volumes at fast speeds with extremely high accuracy and repeatability. This jetting valve offers a significantly higher clock frequency (up to 700 Hz) than conventional dispensing systems with electro-pneumatic actuators and can dispense down to shot sizes of less than 1 nl. The system is made up of the MDV 1560 Jetting Valve and the MDC 1500 Valve Controller.

Using the latest Dynamic Shockwave Technology (DST), which is a revolutionary actuator principle, the valve’s yield is significantly optimised in order to achieve a more precise dispensing result.

Using the latest Dynamic Shockwave Technology (DST), which is a revolutionary actuator principle, the valve’s yield is significantly optimised in order to achieve a more precise dispensing result.

The MDS 1560 Jetting Valve is mountable from any of three sides to dispensing automation or robotics, and has a rotatable fluid box for maximum system integration flexibility. With a bayonet-style fluid box that is easily removable for interchanging of fluids, the tappet change is a fast and easy activity without the need for additional tools. An integrated temperature system, including nozzle heating and monitoring, delivers permanently stable temperatures and ideal viscosity conditions for all dispensing material.

“We have found excellent repeatability using our UV polymer and are impressed with the huge range of adjustments which can be made with the temperature and timing parameters. I had this system up and running in less than 15 minutes.” – display manufacturer

This valve is fully compatible with VERMES Microdispensing consumables and spare parts, giving maximum configuration flexibility.

Features & Benefits

- Very small amounts can be dispensed, jetting down to 1.0 nl or less

- With a dispensing frequency of ~500 Hz, dots or beads can be rapidly applied, including to 3D surfaces

- Driven by Dynamic Shockwave Technology (DST), consistent actuation power delivers high precision and speed, even at the smallest dispense stroke

- Simple set-up and adjustment process

- Parameters can be easily modified on the fly to dispense the perfect pattern

- Integrated heating system for consistent material temperature and optimal viscosity for dispensing

- Easy-to-remove/replace fluid box for straight-forward cleaning or material change

- Readily integrated into automation or robots

Applications

The MDS 1560 can be used in a wide range of applications in industries such as electronics and consumer goods, as well as in medical technology and automotive technology. It is optimised for dispensing the following materials:

- Adhesives & coatings

- Solder pastes from Type 5 and smaller

- Solder fluxes

- Inks

- Oils and greases

- Organic solvents

- All aqueous solutions

Specifications

| Specification | |

|---|---|

| Material viscosity range | up to 2,000,000 mPas |

| Shot size | <1nl up to >20μl |

| Control unit dimensions (HxWxD) | 128mm x 51mm x 189mm |

| Control unit weight | ~550g |

| Valve dimensions (HxWxD) | 100mm x 35mm x 90mm |

| Valve weight | ~390g |

| Inlet pressure range | 0.1 to 100 bar (0.1 to 8 bar with cartridge; 0.1 to 70 bar with pressure tank and metal fluid box) |

| Inlet pressure range (actuator) | 1.5 to 8 bar |

| Response time (PLC interface) | 30μs |

| Dispensing frequency | Max. 700 Hz; average 500 Hz |

| Compatibility | All aqueous fluids, organic solvents, weak acids and bases |

| Position of tappet in absence of actuator pressure | Open |

Ordering Information

| Part number | Description |

|---|---|

| VER1014617 | MDS 1560 Microdispensing System comprising MDV1560 Jetting Valve and MDC1500 Controller |

| VER1014496 | MDV1560 Jetting Valve |

| VER1014497 | MDC1500 Controller for MDV1560 Jetting Valve |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 1.5

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.