IRS 2125 High Performance Flexible Epoxy Adhesive

About IRS 2125 High Performance Flexible Epoxy Adhesive

Also available to buy online at ![]()

IRS 2125 Flexible Epoxy Adhesive is a high performance black resin system. Its combination of flexibility and high adhesive strength lends itself to many high technology bonding, sealing and insulating applications. A two part system with a simple 1:1 mix ratio, it is supplied in a convenient side-by-side double syringe cartridge, complete with static mixing nozzles. Common applications include sealing electronic connections and elevated temperature bonding.

“The IRS2125 epoxy adhesive, performed beyond expectations when applied to seal high pressure hydraulic fluid in a plastic fitting which had sheared. The epoxy set extremely well and passed pressure tests such that it was deemed to be suitable as a permanent seal of the hydraulic system. I would recommend this product as it set rapidly to create an excellent seal and performed well, solving issue with leakage of hydraulic fluids.” – Ian Ross, GMX

Features & Benefits

- Excellent flexibility giving high shear and peel strength

- Tough bonds withstand vibration and flex

- Outstanding chemical and fluid resistance, including moisture, diesel and fuel oils, hydraulic fluid

- Will bond metal, glass, wood, rubber and many plastics, including cable insulations and connector backshells, heat-shrink material

- Will operate at temperatures of up to 150°C

- Can seal to IP68, continuous immersion

- Supplied in 50ml cartridge for easy application

- Long shelf life – 18 months from date of manufacture

Applications

- Cable harness assemblies, wiring, cable joints & terminations, heat-shrink sealing

- Electronics

- Structural bonding

- Downhole and oil well operations

“It is nice to use because you don’t have to pre-mix it, and it has a convenient cure time. The tiles have been solid as a rock. It’s obviously the best!” – Carrie Reichardt, Artist

Specifications

| Specification | ||

|---|---|---|

| Mix ratio | 1:1 resin to hardener | |

| Mixed viscosity | ~ 100,000 cps | |

| Colour | Black | |

| Specific gravity | 1.3 | |

| Pot life | 90 minutes @ 23°C | |

| Cure schedule | Bondline temperature | Time |

| 23°C | 24 hours – handling strength | |

| 23°C | 7 days – full cure | |

| 85°C | 2 hours – full cure | |

| Cured properties (Measurements taken @ 23°C) |

||

| Hardness, Shore D | 50-65 | |

| Temperature range | -75 to 150°C 200°C possible depending on substrate |

|

| Elastic modulus | @25°C – 350MPa @50°C – 90MPa @75°C – 30MPa @100°C – 30MPa @125°C – 30MPa |

|

| Lap shear strength (Al/Al) | 20MPa | |

| Peel strength (XPLE/XPLE) | 370N/25mm | |

| Peel strength after thermal shock (4hrs @ 215°C) | 370N/25mm | |

| Dynamic shear (boot/cable shell size 22) | 520N | |

| Solvent resistance (de-icing fluid, petrol, oil, hydraulic fluid) | Excellent | |

| Dielectric strength | 408 volts/mil | |

| Surface resistivity | 5.5 x 1016 ohm/sq @ 500 volts DC | |

| Volume resistivity | 1.9 x 1012 ohm.cm @ 500 volts DC | |

| Thermal conductivity | 0.4 W/mK | |

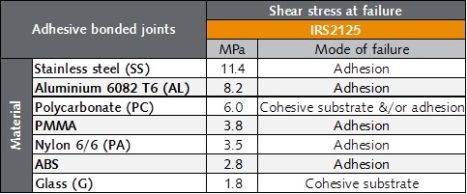

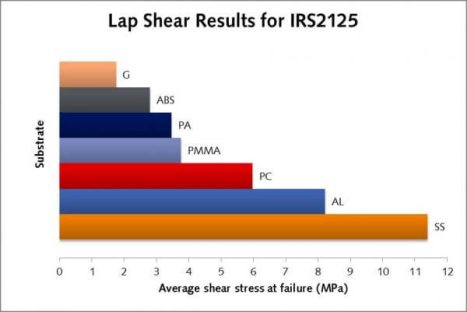

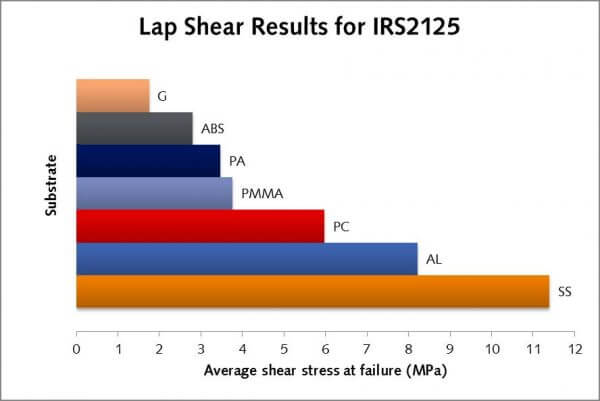

Lap shear results

| Material | Shear stress at failure (MPa) | Mode of failure |

|---|---|---|

| Stainless steel | 11.4 | Adhesion |

| Aluminium 6082 T6 | 8.2 | Adhesion |

| Polycarbonate | 6.0 | Cohesive substrates &/or adhesion |

| PMMA | 3.8 | Adhesion |

| Nylon 6/6 | 3.5 | Adhesion |

| ABS | 2.8 | Adhesion |

| Glass | 1.8 | Cohesive substrate |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

|

Structural Adhesives Selector Guide

Start your adhesive selection process by reading our Structural Adhesives Selector Guide, detailing different chemistries and material specifications. |

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

See how the IRS 2125 works as part of a real application in these adhesive Case Studies:

|

Flexible epoxy adhesive gives strength and durability to mosaic art

British artist Carrie Reichardt relies on our structural adhesives to ensure a strong bond in her creative pieces. |

|

Flexible adhesive improves technical performance

Process Instruments, a UK-based company specialising in water analyser instruments, required a material which could secure their PG13 threads and create waterproof seals in their sensors. IRS 2125 flexible epoxy adhesive was selected due to its strong bond strength, water resistance and straightforward application from convenient cartridges. |

|

Application Insight – Cooling Plate Bonding

Bonding and sealing of cooling plates to fuel calls using IRS 2125. |

Our Technical Bulletins & Articles page has links to:

- Technical Bulletin: Instructions: 50ml Side-by-Side Double Syringe Cartridges

All Downloads

Ordering Information

IRS 2125 is available in a convenient side-by-side double syringe cartridge.

The IRS 2125-50KIT contains a 50 gram cartridge of epoxy, a Syringe Gun and three static mixing nozzles. It is ideal for product evaluations or small quantity users.

Storage: Store in the original unopened containers under cool dry conditions between 15° and 25°C.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 4.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.