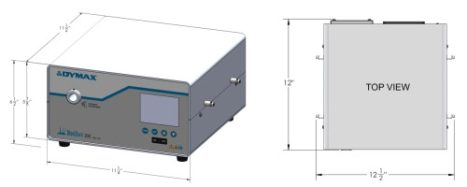

Dymax BlueWave® 200 UV Curing Spot Lamp with Intensity Adjustment

DYM 41013

About Dymax BlueWave® 200 UV Curing Spot Lamp with Intensity Adjustment

The Dymax BlueWave 200 UV curing spot lamp offers very high intensity and simple operation in a versatile, user-friendly and reliable system.

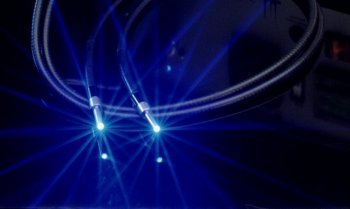

The BlueWave 200 is a high intensity, light curing spot lamp system. This spot curing lamp emits energy in the UVA and visible portion of the spectrum (300-450 nm) for light curing of adhesives, coatings, and encapsulants. Suited for either manual or automated processes, the unit contains an integral shutter which can be actuated by a foot pedal, from the front panel, or from PLC/automation and a universal power input that provides consistent performance at any voltage. A wide range of lightguides in various materials and configurations is available for use with this unit, providing application flexibility.

The new faceplate design features an improved operator interface with an easy-to-read LCD display, which is suitable for use in cleanrooms. The unit also features a patented intensity adjustment control, which is important for validating an appropriate intensity range and maintaining that range during production. Intensity measurement is easily accomplished with the Dymax ACCU-CAL™ 50 radiometer. Scheduled intensity measurements taken during the production process will indicate whether additional intensity adjustments are required. This method of measurement provides the most accurate readings as they are taken through the lightguide in the actual production setting.

Control & Intensity Adjustment

Validation of a UV curing process identifies a minimum acceptable intensity range which ensures complete cure in an acceptable cycle time. Users can choose to operate at full intensity (intensity adjusted to 100%) or maintain a constant intensity (at some lower level) through periodic manual adjustments. The average BlueWave 200 bulb will typically degrade <1% per eight hours of normal use. The good manufacturing practice of routine intensity measurement with a calibrated radiometer will determine when and if any adjustments are required.

Features & Benefits

- More than 17,000 mW/cm² initial intensity for fast, reliable cures

- Patented intensity adjustment feature, giving you full control

- Easy-to-read, back-lit front panel LCD display with enhanced unit status and notification displays

- Improved user interface for easier operation

- Up to 2,000 hours useful bulb life, 2,000 hours bulb warranty

- Integral shutter with digital timer

- Foot pedal or PLC integration

- Proprietary “Cool Blue™” filter virtually eliminates lightguide degradation

- Wide range of lightguides available (liquid/fibre, single/multi-pole, various lengths)

- Bulb changes in less than one minute

- Universal power input operates worldwide

- Controlled power-up sequence ensures correct intensity is achieved before use

- Smooth front panel surface that is easy to clean, suitable for cleanroom use

Specifications

| Specification | |

|---|---|

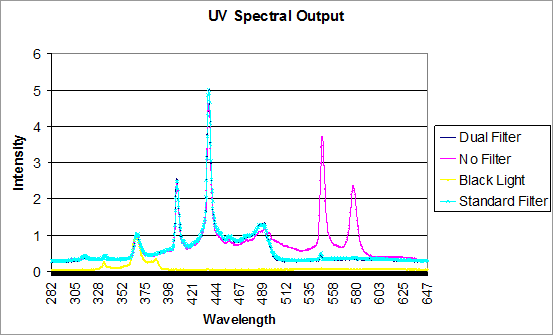

| Intensities | Total (280-450nm) 40+ W/cm² Visible (400-450nm) 17+ W/cm² UVA* (320-395nm) 17+ W/cm² UVB (280-320nm) 7 W/cm² |

| Intensity adjustment | Manual from 1% to 100% output |

| Power requirements | 100-220 VAC, 50-60 Hz, 2.5 amps |

| Power supply | Solid state, 200 Watt |

| Bulb | 200 Watt metal-halide bulb included; replacement in less than one minute |

| Shutter timer | Digital LCD timer up to 9,999.99 seconds; also simple manual open/close operation |

| Shutter activation | Foot switch, panel switch or PLC |

| Reflector | Elliptical; glass with dichroic coating to reflect UV and minimize IR |

| I/O Port | 15 pin D – sub-miniature connector |

| Signals (PLC integration) | Inputs: Shutter activate, shutter deactivate, lamp control, PLC enable

Outputs: Unit status, temperature fault, shutter fault, lamp status, power status, shutter status, lightguide status, bulb life warning, bulb life expired |

| Cooling | Filtered, fan arrangement; thermally controlled to maintain proper lamp temperature |

| Dimensions (L x W x H) | 305 x 318 x 165 mm |

| Weight | 5.78 kg |

| *Measured through a lightguide simulator with a DYMAX ACCU-CAL 50 Radiometer Optional filters available |

|

Lightguides

Recommended Lightguides

| Part number | Description (liquid filled, quartz fibre also available) |

Minimum initial intensity (W/cm²) | Typical intensity at 2000 hours (W/cm²) |

|---|---|---|---|

| DYM5720 | Single pole 5mm x 1m | 17.0 | 8.0 |

| DYM5721 | Single pole 5mm x 1.5m | 16.0 | 7.5 |

| DYM5722 | Single pole 8mm x 1m | 13.0 | 6.5 |

| DYM38476 | Two pole 3mm x 1m | 10.5 | 5.2 |

| DYM38477 | Three pole 3mm x 1m | 9.0 | 4.5 |

| DYM38478 | Three pole 3mm x 1m | 7.4 | 3.7 |

|

|

|

|

|

|

Other Information

|

Top Tips for getting the best from your UV curing process

Read through our easy-to-follow guide on UV curing to maximise your processes productivity. |

Find out more about the technology behind the Dymax BlueWave 200 by reading our technical bulletins and white papers:

See how the Dymax BlueWave 200 works as part of a real application in this UV curing adhesive and equipment Case Study:

|

Electronic Textiles Development Benefits from UV Curing Resin and Precise Dispensing A manufacturer of landing gear and actuation systems for the aerospace market was looking for efficiencies in their electroless nickel plating process. They wanted to automate the masking process and increase throughput, which they achieved with Dymax SpeedMask 7601 and a Dymax BlueWave 200 UV curing lamp. |

All Downloads

Ordering Information

| Part number | Description |

|---|---|

| DYM41013 | BlueWave 200 3.1 UV Curing Spot Lamp |

| DYM38465 | 200 Watt replacement bulb |

Let’s start by talking about your application

- Last updated: July 2023

- Version: 5.9

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.