Dymax UV & Visible Light Curing Plastic, Glass and Metal Bonding Adhesives

About Dymax UV & Visible Light Curing Plastic, Glass and Metal Bonding Adhesives

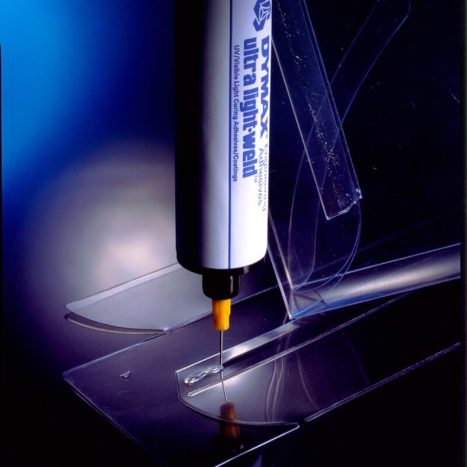

Dymax UV Light Curing adhesives for plastic, metal and glass bonding cure in seconds upon exposure to ultraviolet light and/or visible light, even through UV blocked plastics. A solvent-free, worker-friendly plastic adhesive forms high-strength, environmentally resistant bonds to plastics and other substrates, including polycarbonate, PVC, phenolic, acrylic (PMMA), metal, glass and ceramic. Because plastic adhesives bond so many different substrates, they are exceptional adhesives for bonding dissimilar materials, something that cannot be done with traditional welding methods and other types of adhesives. Typical UV plastic adhesive applications include display case construction, automotive headlamp assembly, novelty bonding, sign assembly, adhering light fixtures and awards and plastic package assembly.

“It became clear at an early stage that a UV and visible light cure adhesive was the only way to do the job. It would give us the opportunity to apply, assemble and inspect at our leisure so we could ensure full coverage and no bubbles. We were able to then wipe off any excess after adjustment and light cure in seconds so we could move on to assemble the next block almost instantly and with full confidence in the integrity of the work we were building up.” – Alex Abbott, Dauphin Restoration Ltd

Please see our page dedicated to Dymax UV light curing adhesives for glass bonding.

Features & Benefits

- Bond in seconds

- Cures with UV and/or visible light

- Suitable for a variety of plastic, metal and glass substrates

- Suitable for bonding dissimilar substrates together

- Blue and red fluorescing formulations for improved inspection and quality control

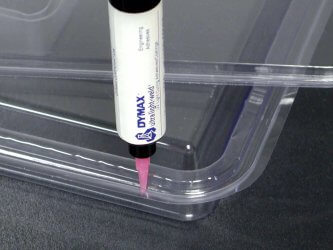

- See-Cure versions provide confirmation of correct application and cure

- Solvent free

- Environmentally friendly

Substrates

Download the full Dymax industrial adhesives selector guide to determine which adhesive(s) is compatible with your substrates, or contact us for advice.

| Substrate | Chemical name | Registered Trademark |

|---|---|---|

| ABS | Acrylonitrile-butadiene-styrene | Lustran ®, Terluran ®, Cycalloy ® |

| FR4 | Epoxy Fibreglass | |

| LDPE | Low-Density Polythene | |

| PA | Polyamide | Nylon* |

| PBT | Poly (butylene terephthalate) | Valox* |

| PC | Polycarbonate | Makrolon ®, Lexan®, Apec®, Calibre® |

| PEI | Polytherimide | Ultem® |

| PES | Polyester Sulfone | Ultrason®, Udel® |

| PETG® | Copolyester | Easter® |

| PI | Polyimide | Kapton® |

| PMMA | Poly (Methyl Methacrylate) | Acrylic, Plexiglass®, Perspex®, Cryolite® |

| PP | Polypropylene | |

| POP | Poly (Phenylene Oxide) | Noryl® |

| PPS | Poly (Phenylene Sulfide) | Ryton® |

| PS | Polystyrene | Novacor®, Styron® |

| PSU | Polysulfone | Ultrason® |

| PUR | Polyurethane | |

| PVC | Polyvinyl Chloride | |

| SAN | Styrene-acrylonitrile | Lustran® |

| AI | Aluminium | |

| CU | Copper | |

| ® Registered trademarks and trademarks acknowledged. | ||

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Selector Guide

| Adhesive | Applications | Adhesive features |

|---|---|---|

| Most popular products | ||

| Dymax 3069 DYM 3069 |

Electrical bonding; potting; wire harness assembly; bonds to polycarbonate, PVC, polyurethane, PET | Low stress; clear; environmentally resistant; adheres to most surfaces; good for flexible and rigid substrates |

| Dymax 3094-T-REV-A DYM 3094-T-REV-A |

Bonding display cases, shelves; laminating plastic sheets; packaging; bonds to acrylic, ABS, styrene, polycarbonate, polyurethane | UV light and/or visible light curing; dispenses easily and cures quickly for precise quantity and placement of adhesive; bonds generally exceed the strength of substrates bonded, including PVC alloys, which resist most other bonding methods |

| Dymax 3099 DYM 3099 |

Bonding clear and translucent acrylic, PMMA, polycarbonate, PVC alloys, and polyurethane. Bonding point-of-sale plastics | Resilient adhesive with excellent adhesion to acrylic (PMMA). Clear, low viscosity UV cured adhesive produces clear, bubble-free bond lines. Can be cured with LED curing lamps. |

| Dymax 6-621 DYM 6-621 Dymax 6-621-GEL DYM 6-621-GEL |

Glass/metal bonding to phenolic and filled plastics | High tensile strength; suited for rigid adhesive applications; clear, hard bonds; cures with UV light or heat |

| Dymax 500-E-REV-A DYM 500-E-REV-A |

Suitable for gaps <0.001 to 0.020, suitable for plastics, glass metals, ferrite bonding, magnet bonding and motor assembly | Cure of Dymax Multi-Cure® adhesives (600 and 800 series adhesives) in areas not able to see light or heat, strong structural bonds, fixtures in seconds, solvent-free |

| Dymax 501-E-REV-A DYM 501-E-REV-A |

Suitable for gaps <0.001 to 0.020, suitable for plastics, glass metals, ferrite bonding, magnet bonding and motor assembly | Cure of Dymax Multi-Cure® adhesives (600 and 800 series adhesives) in areas not able to see light or heat, strong structural bonds, fixtures in seconds, solvent-free |

| See-Cure Adhesive Technology | ||

| Dymax 3220-SC DYM 3220-SC Dymax 3220-GEL-SC DYM 3220-GEL-SC |

Bonding and laminating plastics including PVC, PC, ABS, PET, PEBA, and PU | See-Cure adhesives appear blue when dispensed and become clear when fully cured. This allows users to know where the adhesive has been applied, as well as if the adhesive is fully cured; flexible |

| Dymax 3221-SC DYM 3221-SC |

Bonding and laminating plastics including PMMA, PVC, PC, PU, PA, PET, and ABS | See-Cure adhesives appear blue when dispensed and become clear when fully cured. This allows users to know where the adhesive has been applied, as well as if the adhesive is fully cured; flexible; multi-substrate adhesion |

| Dymax 3225-T-SC DYM 3225-T-SC |

Appliance assembly; plastics assembly; plastics lamination; metal-to-plastic bonding | See-Cure adhesives appear blue when dispensed and become clear when fully cured. This allows users to know where the adhesive has been applied, as well as if the adhesive is fully cured; flexible; multi-substrate adhesion |

| Other plastic bonders | ||

| Dymax 3013 DYM 3013 |

Bonding transparent or translucent acrylic, metal, polycarbonate, PVC alloys, ABS, polyurethane and polystyrene | Resilient; general purpose; low viscosity; moisture resistant; flexible; dispenses easily and cures quickly for precise quantity and placement of adhesive; built-in fluorescence provides a method to insure in-line quality control utilizing optical scanners |

| Dymax 3030 DYM 3030 |

Plastic housing assemblies; appliance, auto and aerospace assemblies | Ultra fast-cure for wide variety of plastic substrates; formulated for fast on-demand cure with LED curing lamps. |

| Dymax 3031 DYM 3031 |

Plastic housing assemblies; appliance, auto and aerospace assemblies | High adhesion; designed for rapid bonding of a wide range of plastic substrates; formulated for fast on-demand cure with LED curing lamps. |

| Dymax 3072 DYM 3072 |

Electrical potting and sealing; bonds to PBT, Valox®, metal, glass, PVC, SAN, PS and K-Resin® | UV and/or visible light curing; dispenses easily to allow for precise quantity and placement of adhesive; bonds generally exceed the strength of substrates bonded, including PVC alloys, which resist most other bonding methods. Can be cured with LED curing lamps. |

| Dymax 3083 DYM 3083 |

Sealing PET & R-PET clamshell packages | Strong bonds to thermoformed PET and R-PET |

| Dymax 3086 DYM 3086 |

Packaging; bonds to SAN, ABS, CAP, MBS, acrylic, glass, ceramic and metal | Very fast; structural strength adhesive; hard, rigid bonds; UL94 V-0 flame class rating |

| Dymax 3113-UR DYM 3113-UR |

Bonding and sealing, plastic window bonding, appliance and plastics assembly | Ultra-Red fluorescing; resilient; general purpose; moisture resistant; adhesion to a wide variety of substrates and plastics |

| Dymax 3130-UR DYM 3130-UR |

Appliance bonding and assembly, plastic housings, displays | Very fast curing plastic bonder; moisture resistant; can be cured with LED curing lamps; Ultra-Red fluorescing |

| Dymax 3169-UR DYM 3169-UR |

Flexible lamination, plastic housing assembly and bonding, loud speaker assembly | Ultra-Red fluorescing; flexibility for laminating and plastics bonding; adhesion to a wide range of plastics and substrates |

| Dymax 3401 DYM 3401 |

Plastic bonder with secondary moisture cure – designed for rapid bonding of a wide variety of plastic and metal substrates and is ideally suited for PC and ABS bonding applications | Superior bond strength and formulated with a UV/Visible light and secondary ambient moisture-cure system for curing in shadow areas. Moisture and thermal resistant, low shrinkage, fluoresces blue under low-intensity black light” for easy in-line inspection. Can be cured with LED curing lamps.” |

Other Information

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

See how Dymax 6-621, Dymax 3099 and Dymax 3225-T-SC work as part of real applications in these UV curing adhesives Case Studies:

|

Fast curing metal bonding solution for Ford Components

A machining and component manufacturing application to bond metal parts efficiently with a minimal bond line on a production scale level. |

|

Acrylic bonding – when it absolutely must look right

A UV adhesive and curing application that required a quick, clear and clean finish. |

|

UV adhesive cures time problem for Brandon Medical Ltd

Timing of production processes have been reduced and the opportunity for better quality control measures are aided by Dymax See-Cure technology. |

All Downloads

- Last updated: November 2022

- Version: 10.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.