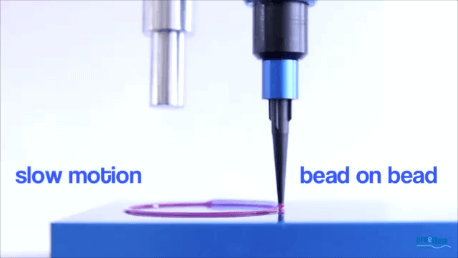

To ensure the required aspect ratio (height v base width) for liquid seals or gaskets, the sealant can be applied as a series of beads, one on top of the other. We call this bead-on-bead.

With this methodology, a set height can be achieved with a small or specified base width. Often UV curable adhesives are used for this task, because they cure very quickly and reliably. In this way, the seal or gasket height can be readily built up in a series of steps. UV curable adhesives, sealants or gaskets are available with the correct properties (adhesion, elasticity, hardness, compression, etc).

In this illustrative video, a UV curing material from Dymax is applied using a robot fitted with a preeflow eco-PEN precision volumetric dosing unit fitted to a robot. The precisely dosed seal or gasket is cured almost instantly using UV light, before the next layer is added. Terminology used is Form-in-Place (FIP) or Cure-in-Place (CIP).

Extra excitement is provided by the use of leading edge LED UV curing equipment, and the material features Dymax’ See-Cure technology, which incorporates a colour change upon cure.

Categories: dispensing, gaskets, LED Curing, robotics, uv curing