Opti-tec 5012 Low Viscosity, Clear Epoxy Adhesive / Encapsulant

About Opti-tec 5012 Low Viscosity, Clear Epoxy Adhesive / Encapsulant

Also available to buy online at ![]()

Opti-tec 5012 is a two component, low viscosity epoxy with very high optical clarity. It has a long pot life and can be cured at room temperature or at 80°C for 90 minutes. Opti-tec 5012 is designed for potting, encapsulation and adhesion of components where high optical clarity, good wetting and low viscosity are important.

Opti-tec 5012 can be used for bonding glass, quartz, metal and many plastics. It finds uses in assembly and repair of glass items where a clear adhesive is required.

Features & Benefits

- High optical clarity, water white with excellent resistance to yellowing

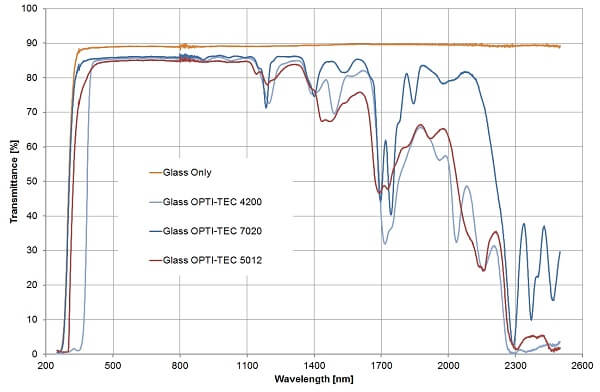

- Excellent transmission down to 300 nm

- Low viscosity (500 cps)

- Long pot life

- Cures within 48 hours at room temperature. Cure can be achieved in 90 minutes at 80°C.

- Opti-tec 5012 has high surface energy. This and its low viscosity allows it to readily wet and wick between surfaces. It develops strong adhesion to most materials used in optics, including metals, ceramics, glass and most plastics.

- Good impact and thermal shock resistance, with low internal stresses due to low shrinkage on cure

- Opti-tec 5012 is a hard, glass-like material after cure and can be polished

- Good chemical and moisture resistance with a very low exotherm, suitable for sensitive potting and encapsulation applications

- Opti-tec 5012 features low fluorescence

Applications

- Optical assembly, optical filters, lenses, prisms

- Glass bonding

- Plastic & glass fibre optics

- Opto-electronics, photonics, LED

- Optical encapsulation & glob topping, casting, potting

- Repair of glass, wood, ceramic

- Potting or encapsulation where high optical clarity is required: geology samples, relics and artefacts, tissue samples

Specifications

| Typical properties | ||

|---|---|---|

| Mix ratio | 100:35 resin to hardener | |

| Mixed viscosity | 0.5-1.0 Pa.s (500-1000 cps) @ 25°C | |

| Colour | Water white | |

| Specific gravity | 1.05 | |

| Pot life @ 23°C | 4 hours (< 25g mix) 8 hours (< 4g mix) |

|

| Max suggested mix | 100 grams | |

| Cure schedule | Bondline temperature 25°C 80°C |

Time 48 hours 90 mins |

| Note: Optimal cured properties are achieved by curing at a bondline temperature of 80°C. | ||

| Cured properties (90 minutes @ 80°C) |

||

| Glass transition temperature (Tg) | 70°C | |

| Hardness, Shore D | 82 | |

| Temperature range | -60 to 200°C | |

| CTE | 50-60 ppm/°C | |

| Lap shear strength (Al/Al) | 3000 N | |

| Optical transmission | >97% @ 300-900 nm; excellent to 2500 nm | |

| Refractive index | 1.56 est. | |

| Dielectric strength | 20kV/mm est. | |

| Dielectric constant | 3.1 est. | |

| Volume resistivity | >1014 est. | |

| Shelf life | 12 months in original sealed containers | |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

|

Structural Adhesives Selector Guide

Start your adhesive selection process by reading our Structural Adhesives Selector Guide, detailing different chemistries and material specifications. |

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

Ordering Information

Packaging

Opti-tec 5012 is available in twinpacks or in bulk.

The twinpack is a clear film sachet, with the resin and hardener separated by a removable clip and rail divider. Click here for twinpack mixing instructions.

Standard twinpack size is 4g total weight. Opti-tec 5012 twinpack sachets are packaged in quantities of 5, sealed into a protective aluminium foil pouch.

Storage: Store in the original unopened containers under cool dry conditions between 15° and 25°C.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 5.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.