flowplus16 Compact Inline Fluid Sensor

VIS 21089

About flowplus16 Compact Inline Fluid Sensor

flowplus16

The ViscoTec flowplus16 compact inline fluid sensor delivers optimum process assurance for fluid dispensing or dosing applications. It finds application in critical processes where the highest levels of quality control are mandated, or where simple, reliable fluid pressure sensing is required.

By measuring the pressure of the liquid being dispensed or dosed, the flowplus16 provides precise monitoring of flows up to 100ml/min, enabling you to achieve consistent results by detecting issues such as inconsistent material feed, clogging needles or nozzles, unsuitable needle-to-substrate distance or the presence of air bubbles in the fluid.

For laboratory or analytic work, the flowplus16 will deliver pressure and flow information, and can analyse static and dynamic application flow mechanics using the output and appropriate software.

flowplus QC control monitor

The ViscoTec flowplus QC control monitor is designed and produced for the monitoring of dosing processes. Up to two pressure sensors can be attached. The pressure values determined from the measurement signals are shown on it’s 5” colour touch screen.

When used in conjunction with the flowplus16, the monitor outputs signals from the flowplus16 into visual lines on the screen. Unstable or pulsating flow rates, e.g. pressure variations can be individually selected and evaluated to optimise your process. The intuitive user guidance of the software and the user-friendly touchscreen grant optimal process control for your application.

Features & Benefits

- Helps achieve optimum dispensing/dosing process control

- Precise flow pressure measurement

- Simple to connect and integrate

- Industry-standard output signal

- Can be used with all fluids

- FDA-certified interior surface

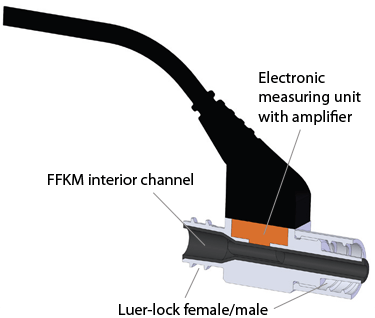

- Compatible with all media via an FDA-certified FFKM perfluoroelastomer interior surface

- No dead space in the sensor

- Connects with any commercial PLC or intelligent evaluation system via M8 connector

- Standard 0-10V output signal

- Built-in signal amplifier eliminates need for external transducers or boosters

- Standard luer lock fitting at both ends

- Easy to install and integrate into existing dispensing or dosing systems

- Maintenance-free, easy to clean

- Can be used in static or moving applications

Applications

Measurable, consistent liquid flow enabled by the use of flowplus16 and flowscreen helps users to guarantee reliability, safety and standards compliance in a wide range of industries, including:

- Life Sciences

- Laboratory

- Pharmaceutical

- Research & Development

- Electronics & Microelectronics

- Photonics

- Process Engineering

- Industrial

- Education & Academia

Specifications

| Technical specifications of the flowplus16 | |

|---|---|

| Flow rate | up to 100ml/min * |

| Measurement parameters | 0 to 16 bar/overload 25 bar |

| Input voltage | 12-30VDC |

| Material | Housing – coated aluminium. Interior flow channel – FFKM. Molding – TPU. |

| Signal | 0.1 to 10V |

| Electrical connection | Push-pull connector/M8 sensor plug |

| Mechanical connection | Luer lock DIN EN 1707 |

| Operating temperature limits | 15°C to 45°C |

* Depends on the viscosity and primacy pressure of the medium

| Technical specifications of the flowscreen | |

|---|---|

| Input / output signals | Input: 2x analogue signal 0-10V Output: 1x ready, galvanically isolated |

| Measurement programmes | Graphic display of the measurement values |

| Measurement over a certain time period | Measurement without analysis Measurement with analysis over max. 2 measurement windows and 1x envelope curve (freely configurable) |

| Constant measurement | Measurement without analysis Measurement with analysis over max. 1 measurement window (freely configurable) |

| Interfaces | USB (A port) LAN |

| Dimensions L x W x D (cm) | 9.6 x 13.6 x 3.2 |

| Power supply | Mains adapter – 230 VAC / 50 Hz Analysis system – 24V DC |

Other Information

Our Technical Articles and White Papers page has white papers to download about this technology:

- A new fluid pressure sensor for process control and validation in critical dispensing and dosing applications by Peter Swanson

- The flowplus16 Pressure Sensor

See the preeflow flowplus16 as part of a real application in this dispensing and robotics Case Study:

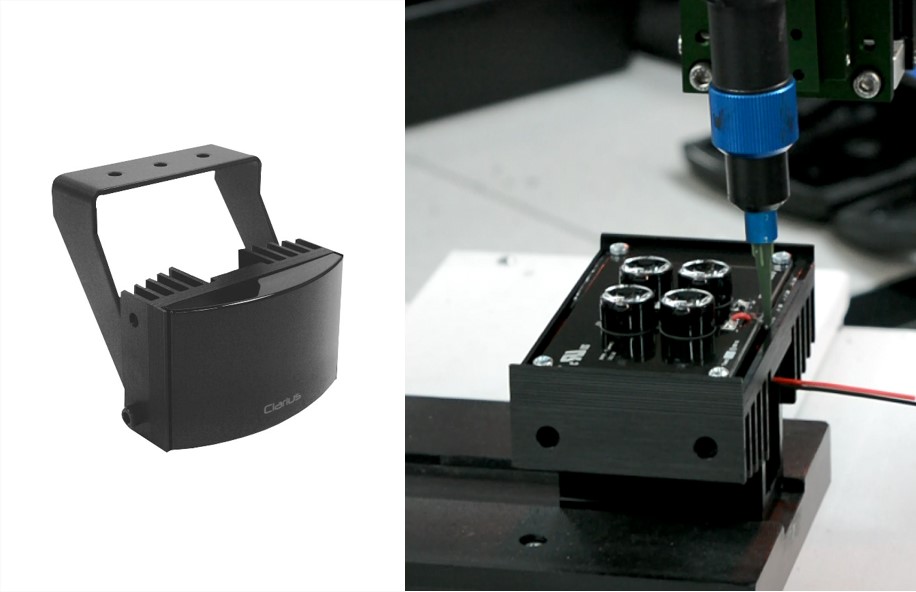

Automated dispensing helps security manufacturer increase throughput and quality

GJD Manufacturing switched to an automated method of dispensing silicone for sealing a plastic lens to aluminium housing. By doing this, they improved the throughput and quality of their white-light and infra-red LED illuminators for the security industry.

Ordering Information

| Part number | Description |

|---|---|

| VIS 21089 | flowplus16 Fluid Sensor |

| VIS 21146 | flowscreen Control Panel Unit |

Let’s start by talking about your application

- Last updated: January 2024

- Version: 4.7

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.