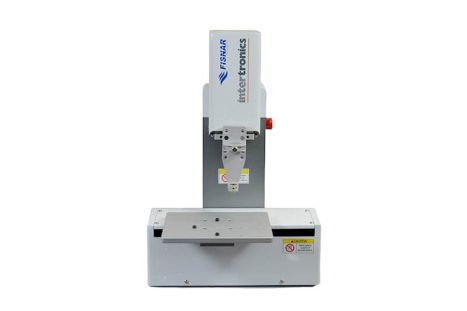

Fisnar F4200N.2 Dispensing Robot

FIS F4200N.2

About Fisnar F4200N.2 Dispensing Robot

The Fisnar F4200N.2 is a compact and economically priced benchtop dispensing robot. Designed for manufacturing, medical and laboratory environments requiring a streamlined, robust and easily maintained machine. This robot will support most light dispensing applications that require a high-performance standard. The bench space reduction is an additional benefit. Programming is simply carried out by a teach pendant (included) using the industry’s leading dispensing software that walks the user through step-by-step instructions to create a sophisticated dispensing operation in minutes.

The Fisnar 4200N.2 has the smallest footprint in the Fisnar series of desktop dispensing robots, making it one of our most popular dispensing machines, with an unbeatable combination of price and performance.

We are able to provide complete dispensing systems including robots like the Fisnar F4200N.2. See some examples of complete dispensing systems here.

Features & Benefits

- Dispenses dots, lines, arcs and circles

- Suitable for adhesives, coatings, gaskets, potting, filling and shielding applications

- Resolution 0.001mm/axis

- Continuous path motion and point to point

- Step & repeat copy functions

- Automatic offset calculations

- Quick “Fluid Purge” button

- No computer skills required

- 100 programs, 4,000 points per program

- Software tip alignment routine for quick program offsets when changing dispensing tips

- USB connector allows system updates and program interchange between robots

- Fast, accurate and reliable 24 hours a day

Applications

- Adhesives

- Form-in-place (FIP) gaskets

- Potting

- Coating

- Filling

The automation of any manual bench dispensing application can be easy to justify, with a quick return on investment (ROI). By virtue of its very competitive pricing, the F4200N.2 provides a significant cost saving when compared to existing bench robot systems.

The compact Fisnar F4200N.2 handles a dispensing area of 200mm x 200mm and is capable of storing up to 100 different programs. Step-by-step intuitive instructions simplify job creation tasks, allowing a program to be entered and running in minutes. A 16-channel I/O interface provides for communication with external devices for secondary applications and multiple dispensing equipment components. An optional Windows software package with a DXF file converter is available for programming from a computer. A compact, robust, heavy-duty design (cast construction) provides stability when working to fine tolerances.

The robot is a three-axis design and is capable of interfacing with any INTERTRONICS dispensing equipment. The F4200N.2 can use simple dispensing barrels, controlled by a pneumatic dispenser, or a dispensing valve, fed from some form of reservoir. We provide a full turnkey solution. Please contact us for a full discussion of your requirements.

Specifications

| Specification | F4200N.2 |

|---|---|

| Robot working area X/Y/ Z | 200 x 200 x 50mm |

| Tool load – Z axis | 2kg |

| Max. speed X/Y/Z (mm/sec) | 500 / 500 / 200 |

| Repeatability | +/- 0.02mm / axis |

| Resolution | 0.001mm / axis |

| Data memory | 1-100 programs | 50,000 points / program |

| Drive system / stepping motor | Micro stepping motors |

| Motion control | PTP & CP |

| Teaching method | Teach pendant |

| I/O signals | 8 inputs / 8 outputs |

| External interface | USB / RS232 |

| Power supply | Auto-switching AC 100-240 VAC, 320 watts |

| Dimensions (WxDxH) | 324 x 499 x 480mm |

| Weight | 20kg |

Programming

Programming is simple with easy to follow English language instructions. Commands are followed and responses entered by a teach pendant. An LCD display prompts the user for a data input and once confirmed, automatically displays the next instruction. By this method a program can be created quickly and simply.

Other Information

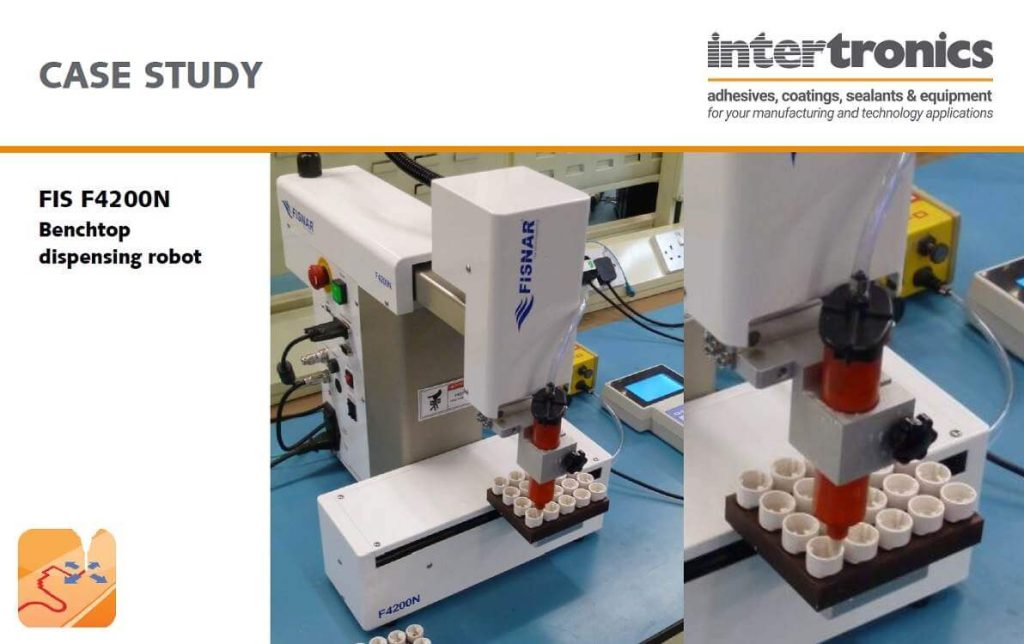

See how the Fisnar F4200N works as part of a real application in this robotics Case Study:

|

CEM increases competitiveness with dispensing robot

Integrating a benchtop dispensing robot into flow line assembly for electronics allowed for a continuous production process. This resulted in reduced wastage, increased quality and increased output. |

|

Precision dispensing helps electrical manufacturer to reduce waste by improving quality and yield

By switching to an automated dispensing system, this electrical manufacturer reduced scrappage and therefore improved quality and yield of their product. |

Our Technical Bulletins & Articles page has links to:

- Robots in Manufacturing – How the Smaller Machine Provides Automation and Competitiveness – by Peter Swanson

|

Achieving ROI with robotics – a roundtable discussion

The benefits of robotics are quite compelling: improved productivity, efficiency, output, quality, and flexibility. In addition to their production benefits, they can improve health andsafety and job satisfaction for employees. To explore the UK’s productivity puzzle and discuss how the UK’s manufacturers can achieve ROI on their robot purchases, we brought together our team and a leading robotics expert. |

|

The 10 Myths abour Dispensing Robots

Are any of these misconseptions about dispensing robots holding back your productivity? |

All Downloads

Ordering Information

| Part number | Description |

|---|---|

| FISF4200N.2 | 200 x 200mm work area benchtop dispensing robot Includes: Teach Pendant, Bracket Mounting Plate, I/O Connectors, Operating Manual |

| FISF4000N-WIN | Windows® software package |

| Enclosure | A range of safety enclosures are available with light curtains, interlocked doors, etc. |

Let’s start by talking about your application

- Last updated: December 2022

- Version: 3.2

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.