DC50 MAX Benchtop Digital Liquid Dispensing Controller

FIS DC50MAX

About DC50 MAX Benchtop Digital Liquid Dispensing Controller

Also available to buy online at ![]()

The Fisnar DC50 MAX Benchtop Digital Liquid Dispensing Controller is a precision time/pressure dispenser with clear, all-digital gauges for the fine-tuned dispensing of dots and beads.

The Fisnar DC50 MAX Benchtop Digital Liquid Dispensing Controller is a precision time/pressure dispenser with clear, all-digital gauges for the fine-tuned dispensing of dots and beads.

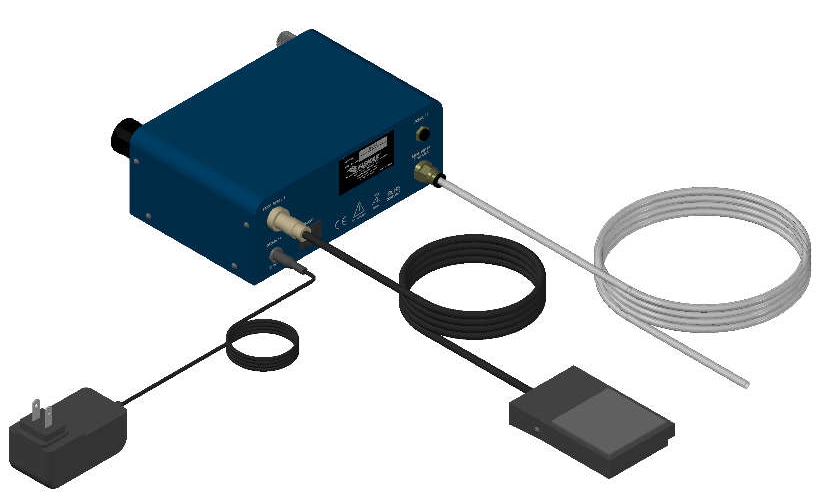

Using two bright, digital displays (one for time, one for pressure), dispensing cycles can be created, dialled in with fine adjustments, and saved to the system’s in-built memory for a repeatable process. The DC50 MAX can be operated using two distinct dispensing modes; a manual-mode, which is controlled using the included foot pedal, and a timed-mode which dispenses for a preset time.

The DC50 MAX is fitted with:

- a precision pressure regulator to ensure the highest levels of dispense control and repeatability, particularly with low to medium viscosity fluids

- a digital pressure gauge for improved process control

A new and improved FSX Syringe Barrel Stand is included with the DC50 MAX which gives the user better storage of the syringe barrel when not in use, preventing the dispense tip from foreign contaminants or accidental damage while also capturing any fluid that may drip. Built in purge trays allow for a small of fluid material to be purged into a clean and contained location when a new dispense tip is attached to the syringe barrel or when checking for correct fluid material flow.

Incorporating an adjustable suck-back feature, the DC50 MAX can prevent post-dispense dripping of low-viscosity fluids as well as the potential for oozing from higher-viscosity creams and pastes, reducing benchtop mess and saving material.

We recommend QuantX syringe barrels and dispensing tips for use with the DC50 MAX. A broad range is available to meet the requirements of your dispensed material and application. We offer dispensing component starter kits to get you off and running quickly.

Features & Benefits

Digital timer control for repeatable dispensing

Digital timer control for repeatable dispensing- Precision regulator & digital pressure gauge ensure precise flow control

- Simple controls let you create your dispense cycle programme within seconds

- Two modes of operation: manual or timed

- Will dispense both low and high-viscosity fluids using an adjustable 0-100psi pressure regulator

- Manufactured with a durable aluminium housing and industry standard pneumatic system components

- Suck-back vacuum feature prevents dripping to minimise workbench mess

- User-friendly touch-sensitive controls

Applications

The DC50 MAX is designed to dispense a wide range of liquids and pastes such as:

- Cyanoacrylate adhesives

- Solvents

- Lacquers

- Adhesives

- Oils

- Greases

- Inks

- Sealants

- Coatings

- Temporary masking

- Solder pastes and brazing pastes

- Flux

- Conformal coatings

In a variety of industries including automotive, semiconductor, loudspeakers, PCB assembly, medical devices, jewellery, sensor manufacturing, connectors, flat panel displays, SMT, general automation, and more.

Specifications

| Specification | |

|---|---|

| Dispense time | 0.008 – 99.99 seconds |

| Cycle rate | Up to 600 cycles/min |

| Relative humidity | 20 – 90% (no condensation) |

| Air input | 100 psi (7 bar) max |

| Air output | 1 – 100 psi (0.07 – 7 bar) |

| Input AC to power supply | 100 – 240 VAC, 50/60 Hz |

| Operating temperature | 10 – 40 °C |

| Weight | 0.97 kg |

| Standards | UKCA & CE approved, RoHS compliant |

| Dimensions (WxDxH) | 192 x 128 x 76 mm |

The DC50 MAX digital liquid dispenser requires clean, dry compressed air for operation. It is recommended that factory air be supplied to the dispenser through a 5-micron filter/regulator. If no factory air is available, we are able to supply a range of low cost, very quiet compressors which are suitable.

Other Information

As standard, the DC50 MAX dispensing controller releases regulated, compressed air through its built-in male push connector fitting. 6mm (1/4”) tubing can be easily hooked-up to the controller, with no additional components required.

|

Introduction to Time/Pressure Dispensing Download a presentation which describes the theory and practicalities of time/pressure dispensing. |

Ordering Information

| Part number | Description |

|---|---|

| FISDC50MAX |

DC50 MAX digital liquid dispenser |

| FIS5601911 | Universal power adaptor (included) |

| FIS5601888 | Foot pedal (included) |

| FIS561851 | Hose assembly – compressed air input (included) |

| FIS5601969 | FSX Syringe barrel stand (included) |

| FIS5779K712 | Push connect fitting – adapts 5/32″ OD tubing to 1/4″ stem (included) |

| Recommended additional items | |

| FISDCK800 |

Dispensing component kit – includes small (3, 5, 10cc) syringe barrels and accessories, and an extensive selection of dispensing tips |

| FISQK-CSK |

Dispensing consumables starter kit – includes all standard syringe barrels (3, 5, 10, 30, 55cc) and accessories, plus a selection of dispensing needles |

| FISQK-NSK |

Dispensing needle sample kit – contains a variety of dispensing needles |

DC50 MAX digital liquid dspenser includes these accessories

DC50 MAX digital liquid dspenser includes these accessories

Let’s start by talking about your application

- Last updated: January 2024

- Version: 1.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.