In time/pressure fluid dispensing, the use of a dispensing piston in the syringe barrel can benefit in a number of ways: a piston helps to apply even pressure across the liquid surface, giving a more uniform dispense, it acts as a barrier between the liquid and the air, and it reduces waste and residue in the barrel. For high viscosity materials which do not self-level, the use of a piston in the dispensing barrel can stop “tunneling”, or the drilling of a hole straight through the material by the pressurised air. A piston in the dispensing barrel can help prevent dripping of low and medium viscosity (runny) liquids. It will prevent the barrel adapter assembly and its ‘O’ ring being contaminated. If you are using suck-back on the barrel, a piston helps prevent material or fumes being sucked into the dispensing controller, especially if the syringe barrel is dropped or if the vacuum is turned up too high.

Conventional pistons can cause problems when dispensing very low viscosity, watery fluids such as cyanoacrylate adhesives or solvents. The small amount of friction between the piston and the barrel wall can inhibit precise control under low dispensing pressures. If the cyanoacrylate adhesive is generating a “bloom”, then the piston can get hung up on this residue on the barrel. If you decide to use no piston, then this lack of containment in the barrel raises the risks of spillage or suck-back of fumes or worse into the barrel adapter assembly or dispensing controller.

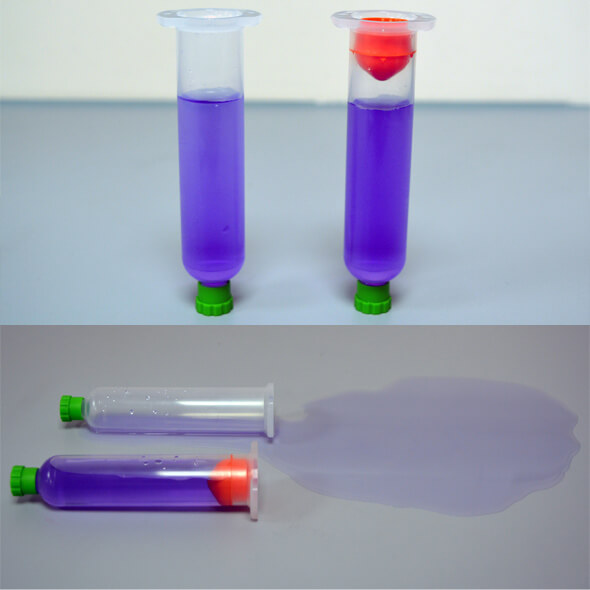

The QuantX Low Viscosity Pistons are designed to to be used when dispensing low viscosity fluids like solvents or cyanoacrylate adhesives. They are inserted into the barrel in the same way as conventional pistons, but are not designed to be pushed in to contact the liquid. They have a small hole in them which allows the low pressure compressed air to pass through and drive the dispensing, but the piston remains near the mouth of the barrel. The Quantx Low Viscosity Pistons provide more dispensing control and accuracy for more runny liquids, help prevent dripping, and stop fumes and liquids from spilling or being sucked into places where you don’t want them!

More help can be found in our 25 Top Dispensing Tips.

Categories: cyanoacrylate adhesives, dispensing, what's new