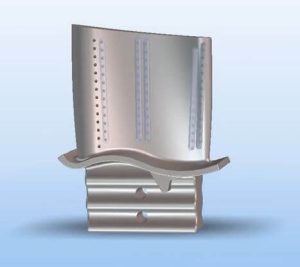

When testing turbine blade air flow, it’s vital that the material used to mask the cooling holes is up to the job of protecting them from the high-pressure air being blown at the blade. DYMAX SpeedMask® temporary masking resin is perfect for the job.

Applied over the cooling holes, Speedmask is cured with UV/visible light in seconds, making it ready for immediate testing. The cured mask provides optimal protection against the high-pressure air, with no movement or loss of adhesion. After testing is complete on the first row holes, the mask is simply peeled off, and the tested row masked off. No adhesive residue is left on the surface of the blade. The process is repeated for each row until all have been tested.

Watch our animated YouTube video which demonstrates the process.

Categories: masking