Dymax SpeedMask Temporary Masking UV Resins

About Dymax SpeedMask Temporary Masking UV Resins

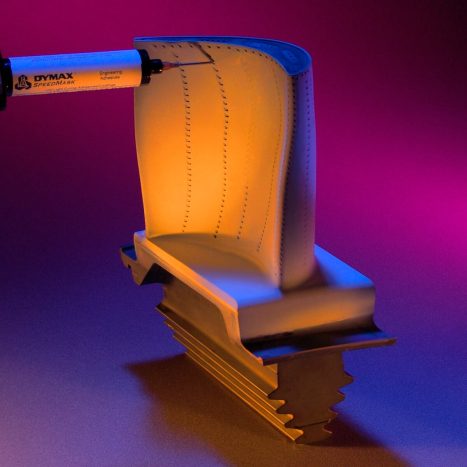

Replace tape, wax, lacquers and fixtures with Dymax SpeedMask temporary masking resins, which offer reliable protection against most metal finishing processing environments. Their tenacious adhesion seals and protects machined, ground, or polished surfaces during tumbling, peening, abrading or cleaning processes.

Grinding and peening masks eliminate external damage to edges and surfaces and internal cavity FOD. SpeedMask resins also seal cavity openings and prevent contamination from acid, alkaline and plating solutions, as well as the debris from air plasma spray, HVOF, peening and grit blasting.

Features & Benefits

- Apply and cure in seconds

- Reduce labour, rework and scrap

- Easy to automate

- Environmentally and worker-friendly

- Metallurgically neutral

- Minimal capital investment

- Major OEM approvals

Applications

Masking for:

- Acid Stripping

- Anodising

- Chemical Milling

- Plating

Dymax advanced technology SpeedMask UV resins, curing lamps and accessories simplify regulatory compliance, and bring efficiency and cost reduction to new parts manufacturing, overhaul and repair, turbine and metal finishing, as well as orthopaedic implant, surgical instrument and medical device component processing. Clean burn-off grades and peelable and water soluble masks are available.

DYMAX SpeedMask is applied |

Dymax SpeedMask is UV cured instantly |

Part is ready for processing |

Part is processed |

DYMAX SpeedMask is removed |

Part is finished |

Selector Guide

| Product name | Description | Viscosity | Hardness | Appearance |

|---|---|---|---|---|

| Thermal Plasma Spray | ||||

| DYMAX 706 | · Acid strip and thermal spray-coating mask · Burn-off removal |

43,000 | D75 | Clear |

| DYMAX 718 | · APS and HVOF resin with aluminium oxide for wear resistance · Burn-off removal |

50,000 | D80 | White |

| Blasting Surface Treatment | ||||

| DYMAX 724 | · Low adhesion · Dry-surface treatment · NVP free · Easy peel |

70,000 | D40 | Clear |

| Mild Plating & Blasting | ||||

| DYMAX 726-SC | · Chemical and heat resistant gel with See-Cure · Blue to Pink · Easy peel |

45,000 | D40 | Blue |

| Plating & Chemical Process | ||||

| DYMAX 728-G |

· Aggressive chemical resistance for plating · Green in colour · Peelable |

25,000 | D55 | Green |

| DYMAX 729 | · Plating and harsh chemical mask · High temperature resistance · High adhesion · Burn-off removal |

20,000 | D70 | Clear |

| DYMAX 7602 |

· Plating, anodising, grit blasting and acid stripping · Colour change upon cure (pink to yellow-green) · Resistant to strong acids and etchants · Easy peel-off removal · LED UV curable |

23,000 | A76 | Pink |

| Plating, Plasma Spray, Blasting & Anodising | ||||

| 717-R |

· Fast curing · Peel-off after hot-water soak · Sprayable · High visibility red colour · ISO 10993 Cytotoxicity approved |

21,000 | D60 | Red |

| DYMAX 730-BT | · Trimmable · Aggressive chemical resistance for plating and anodising · Easy to peel |

20,000 | D36 | Blue |

| DYMAX 731-REV-A | · Aggressive processing mask · High adhesion · Bright yellow in colour · Replacement for 717-R (limited depth of cure) |

18,000 | D55 | Yellow |

| DYMAX 733 | · High adhesion · Aggressive processing mask · Faster cure speed than 717-R and 728-G |

25,000 | D50 | Clear |

![]() = Our most popular products in this range

= Our most popular products in this range

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

See how Dymax SpeedMask works as part of a real application in this Case Study:

|

Improving masking process for electroless nickel plating in Aerospace and Defense applications

A manufacturer of landing gear and actuation systems for the aerospace market was looking for efficiencies in their electroless nickel plating process. Their wanted to automate the masking process and increase throughput, which they achieved with Dymax SpeedMask 7601 and a Dymax BlueWave 200 UV curing lamp. |

|

How MTU Aero Engines is using a liquid mask to revolutionise its surface processing

MTU Aero Engines, a leading German manufacturer of military and civil aircraft engines, sought an efficient and repeatable alternative to manually applied masking tapes for their valuable components. By implementing Dymax Speedmask and automated dispensing equipment to the process, the team at MTU greatly increased throughput, reduced costly rejects, and achieved near zero tolerance levels. |

See our Technical Articles and White Papers page for a technical whitepaper on Environmentally Safe, UV Curable Masking Resins Reduce Aircraft Component Manufacturing Costs – by Rich Golebiewski, Dymax Corp

All Downloads

- Last updated: November 2022

- Version: 7.3

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.