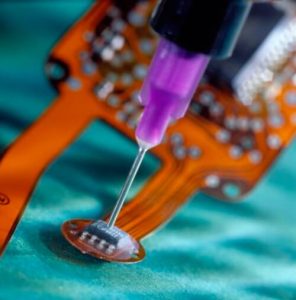

The Dymax 9100 series of light/moisture-cure electronics encapsulants are for protection of small areas of pcb’s where sensitive components can be encapsulated or “glob topped”. What makes them different is that DYMAX Dual-Cure 9101, 9102 and 9103 now have a rapid secondary moisture cure for shadowed areas. The additional curing process gives a more secure cure where the adhesive may flow under the encapsulated device. This could be a chip-on-board (COB) application where there is a need to lend mechanical support to fragile wire connections – or chip-on-flex, chip-on-glass and traditional wire bonding. Equally, they can be used for encapsulating fully packaged devices. Localised protection can be selectively provided for vibration damping, structural integrity, mechanical or environmental protection.

Dymax Dual-Cure 9101, 9102, and 9103 are resilient materials formulated with a UV/visible light cure – and a very quick secondary ambient moisture-cure system. They cure tack free after UV cure, so pcb’s can be handled sooner with less potential for damage. The Dymax 9100 series rapid two-day moisture cure – compared with seven days typical with other systems – shortens the time for further handling as well as final testing and assembly.

These three new materials have varying viscosities of 7,000, 17,000, and 25,000 cP, to match the flow and coverage required of particular applications. This choice allows for performance and dispensing to be optimised with jet dispensable capability for more accurate placement and more efficient material usage. The cured materials are flexible, reducing stress. Unlike other encapsulants, they do not require refrigeration for transportation/storage of the uncured material, nor do they require mixing.

Adding the Dymax 9100 series to our existing coating and encapsulant range provides you with more options in circuit protection.

Categories: electronics, encapsulation, microelectronics, uv curing