Thermally Conductive Adhesives from Polytec PT

About Thermally Conductive Adhesives from Polytec PT

Also available to buy online at ![]()

Polytec PT offers a range of thermally conductive adhesives for technology applications. The products are two-part and single-part epoxy systems designed for all applications where heat transfer is essential, including heat-sinking and ceramic packaging.

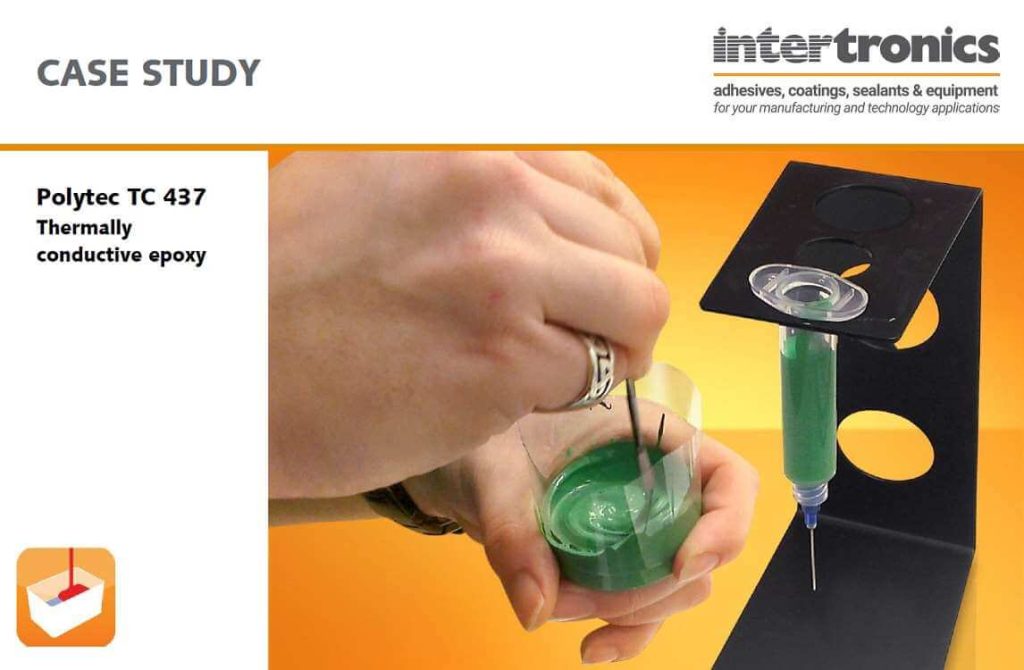

“With Polytec we have about three times the pot life we had before, and the bubbles rise to the top so we can pretty much do what we want with it. Polytec TC 437 is now our preferred material” – Ben Moffat, Variohm

| Processing | Cold-cured | Hot-cured | Hot-cured | Hot-cured |

|---|---|---|---|---|

| Components | 2C | 1C | 2C | 2C |

| Electrically insulating | Yes | No | Yes | No |

| 0-1 W/mK | TC 417-2 TC 437 | - | TC 430 | - |

| 1-2 W/mK | TC 418 | - | TC 420 TC 418 | - |

| 2-4 W/mK | - | - | TC 433 | - |

| 4 W/mK | - | EC 242 Frozen | - | VP 2026 |

Features & Benefits

- Excellent thermal conductivity – up to 4W/mK

- Both ambient and thermal cure options

- Process convenient packaging, including twin-packs, cartridges, and premixed and frozen syringes

- Can bond difficult combinations of materials such as copper and aluminum

- Gap-filling

- Thermally conductive over large areas

- Resistant to most process media such as water, oil or gas

Applications

- Heat dissipation

- Chip bonding

- Heat sink bonding

- Power semiconductors

- Electronics

- Opto-electronics

- Hybrid microelectronics

- Automotive

- Potting sensors and thermistors

- Heat exchangers

- Battery cells

Selector Guide

| Product name | Features | Application |

|---|---|---|

| Polytec TC 351 | · Thermal conductivity (W.m-1.K-1): 0.8 · Number of components: 1 · Temperature range: -55 to +200°C (300ºC short-term) · Consistency: creamy paste · Colour: black |

Polytec TC 351 is a single component, thermally conductive epoxy with good thermal conductivity. It was designed for all applications where electrically insulating and thermally conductive bonds are desirable.

Polytec TC 351 has a conveniently long pot and shelf life which is ideal for high volume dispensing techniques. Typical applications are bonding of sensors in metal holders and fixation of single devices on PCBs. |

| Polytec TC 406 |

· Thermal conductivity (W.m-1.K-1): 2.2 · Number of components: 2 · Mix ratio by volume: 2:1 · Temperature range: -55 to +150°C (240ºC short-term) · Consistency: creamy paste · Colour: white |

Polytec TC 406 is a pasty, two component epoxy which cures at room temperature, used for thermal management in electronics, lighting, hybrid technology, sensor technology and power engineering. It is supplied in a process-convenient side-by-side cartridge, ready for dispensing. |

| Polytec TC 411 |

· Thermal conductivity (W.m-1.K-1): 1.4 · Number of components: 2 · Mix ratio by volume: 2:1 · Temperature range: -55 to +120°C (220ºC short-term) · Consistency: creamy paste · Colour: white |

Polytec TC 411 is a pasty, two component, medium-hard epoxy which cures at room temperature, used for thermal management in electronics, lighting, hybrid technology, sensor technology and power engineering. It is supplied in a process-convenient side-by-side cartridge, ready for dispensing. |

| Polytec TC 417-2 | · Thermal conductivity (W.m-1.K-1): 0.80 · Number of components: 2 · Mix ratio by weight: 100:13 · Temperature range: -55 to +180°C (250ºC short-term) · Consistency: flowable paste · Colour: black |

Polytec TC 417-2 is a two component, thermally conductive, electrically insulating epoxy. It is used in various thermal management applications, like potting of large volumes. It has an excellent chemical and moisture resistance. It has an excellent adhesion to glass, metal, ceramic, FR4 and most plastics. The room temperature cure allows bonding of temperature sensitive substrates very conveniently. |

| Polytec TC 422 |

· Thermal conductivity (W.m-1.K-1): 0.8 · Number of components: 2 · Mix ratio by volume: 2:1 · Temperature range: -55 to +160°C (260ºC short-term) · Consistency: pasty · Colour: blue |

Polytec TC 422 is a pasty, two component epoxy with excellent adhesion, particularly to metals such aluminium and stainless steel. It is used for thermal management in electronics, lighting, hybrid technology, sensor technology and power engineering. It is supplied in a process-convenient side-by-side cartridge, ready for dispensing. |

| Polytec TC 430 | · Thermal conductivity (W.m-1.K-1): 0.7 · Number of components: 2 · Mix ratio by weight: 100:4 · Temperature range: -55 to +250°C (350ºC short-term) · Consistency: thixotropic paste · Colour: yellow |

Polytec TC 430 is a two-component, thermally conductive, electrically insulating epoxy. It is suggested for applications where heat dissipation and insulating properties are required. Typical applications include attaching heat sinks, die attach, die bonding power devices and thermally conductive underfill.

Polytec TC 430 has an excellent adhesion to ceramic, glass, semiconductor materials, ferrous and non-ferrous metals and most plastics. |

| Polytec TC 433 | · Thermal conductivity (W.m-1.K-1): 2.0 · Number of components: 2 · Mix ratio by weight: 100:5 · Temperature range: -55 to +220°C (320ºC short-term) · Consistency: thixotropic paste · Colour: white/brown |

Polytec TC 433 is a thixotropic, two component, highly thermally conductive, electrically insulating epoxy for thermal management in micro and power electronics, energy engineering etc. It has an excellent adhesion to ceramic, glass, semiconductor materials, ferrous and non-ferrous metals and most plastics. |

| Polytec TC 437 | · Thermal conductivity (W.m-1.K-1): 0.6 · Number of components: 2 · Temperature range: -55 to +180°C (230ºC short-term) · Mix ratio by weight: 10:1 · Consistency: thixotropic paste · Colour: white/yellow |

Polytec TC 437 is a two-component, thermally conductive electrically insulating epoxy which can be cured at room temperature within 16 hours. Typically applications include attaching heat sinks, thermally conductive underfill, thermistor potting, die attach and heat management for power semiconductor devices. Excellent adhesion to ceramic, glass, semiconductor materials, metals and most plastics. |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

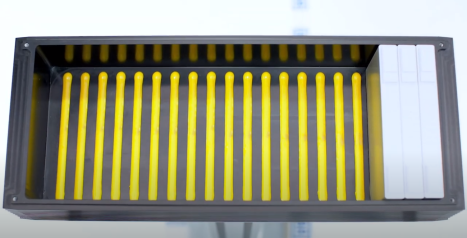

See how Polytec TC 437 works as part of a real application in this Potting Compound Case Study:

|

We pot the green for Variohm with custom thermal potting compound

Potting compound requiring good thermal conductivity and an extended pot life in a custom made colour. |

- Last updated: January 2024

- Version: 7.2

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.