Polytec PT Thermally Conductive Adhesives in Cartridges

About Polytec PT Thermally Conductive Adhesives in Cartridges

Also available to buy online at ![]()

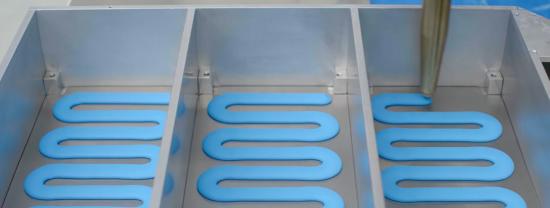

Polytec PT Thermally Conductive Adhesives are packed in 50ml side-by-side cartridges for convenient manual processing. Polytec TC 406, Polytec TC 411 and Polytec TC 422 are two-component epoxies that cure at room temperature and are used for thermal management in electronics assembly, hybrid circuits, sensor manufacture and power engineering.

- Polytec TC 406 offers some of highest thermal conductivity available in cartridge-packaged epoxies (2.2 W/mK)

- Polytec TC 411 has very good thermal conductivity (1.4 W/mK) alongside a Shore D 38 hardness for extra flexibility and resilience

- Polytec TC 422 offers an easy-to-process 50,000 cP viscosity for good flow characteristics

We also offer several other thermally conductive adhesives from Polytec, supplied in bulk containers, twin-packs, or premixed and frozen syringes.

| Polytec TC 406 | Polytec TC 411 | Polytec TC 422 | |

|---|---|---|---|

| Mechanical properties | rigid | flexible | rigid |

| Thermal conductivity | 2.2 W/mK | 1.4 W/mK | 0.8 W/mK |

| Temperature stability | good | good | good |

| Adhesion to Al | very good | very good | very good |

| Adhesion to cataphoretic paint | very good | very good | very good |

| Adhesion to PA | very good |

Features & Benefits

- Cartridge packaging allows for simple processing

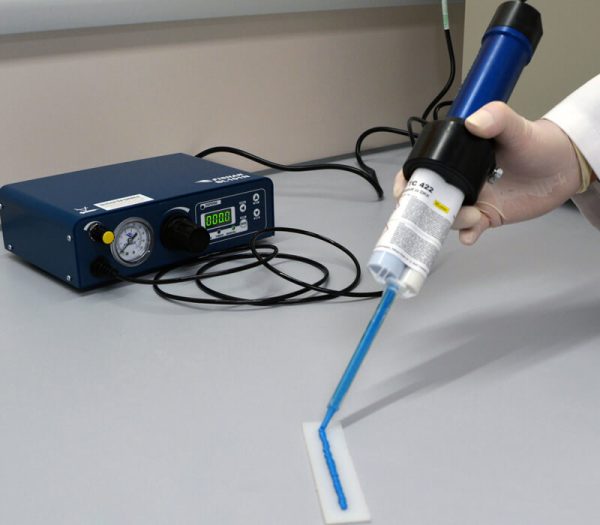

- Application direct from the cartridge with a static mixing nozzle, using a dispensing gun

- Adhesives are supplied in the correct mixing ratio

- High thermal conductivity, particularly with Polytec TC 406

- Electrically insulating

- Flexible version available (Polytec TC 411)

- Cures at room temperature; curing can be accelerated with heat

- Room temperature storage

These cartridge-packaged adhesives can be easily dispensed with a simple dispensing gun or with a Fisnar DTD50 50ml cartridge dispenser

Specifications

| Specification | Method | Polytec TC 406 | Polytec TC 411 | Polytec TC 422 |

|---|---|---|---|---|

| Colour when mixed | TM 101 | white | white | blue |

| Mix ratio by volume | – | 2:1 | 2:1 | 2:1 |

| Pot life at 23°C (h) | TM 702 | 0.5 | 2 | 1 |

| Shelf life at 23°C (months) | TM 701 | 12 | 12 | 12 |

| Consistency | TM 101 | pasty | pasty | pasty |

| Specific gravity when mixed (g/cm³) | TM 201.2 | 1.9 | 1.5 | 1.9 |

| Viscosity when mixed at 23°C (cP) | TM 202.1 | 180,000 | 140,000 | 50,000 |

| Hardness (Shore D) | DIN EN ISO 868 | 85 | 38 | 85 |

| Max. service temperature (continuous) (°C) | TM 302 | -55 / +150 | -55 / +120 | -55 / +160 |

| Max. service temperature (short-term) (°C) | TM 302 | 240 | 220 | 260 |

| Degradation temperature (°C) | TM 302 | 300 | 280 | 310 |

| Glass transition temperature (Tg) (°C) | TM 501 | 65 | <20 | 65 |

| Thermal conductivity (W/mK) | TM 502 | 2.2 | 1.4 | 0.8 |

| Young’s Modulus (N/mm2) | TM 605 | 5000 | n.d. | 7500 |

| Tensile strength (N/mm2) | TM 605 | 27 | 3 | 44 |

| Lap sheer strength (AI/AI) (N/mm2) | TM 604 | 14 | 7 | 19 |

| Elongation at break (%) | TM 605 | 3.5 | 11 | 1.2 |

| Dielectric strength (V/mm) | – | 10 | – | – |

| Min. curing temperature (°C) | – | 15 | 15 | 15 |

| Curing time at 23°C (h) | – | 24 | 48 | 24 |

| Curing time at 80°C (min) | – | 60 | 90 | 60 |

| Flammability | – | UL94 V-0 | – | – |

Ordering Information

Let’s start by talking about your application

- Last updated: January 2024

- Version: 1.8

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.