preeflow® eco-DUOMIX450 Precision Metering, Dynamic Mixing and Dispensing System

About preeflow® eco-DUOMIX450 Precision Metering, Dynamic Mixing and Dispensing System

The preeflow eco-DUOMIX450 is a high precision volumetric metering, mixing and dispensing unit which is designed to process two-component materials with extraordinary control.

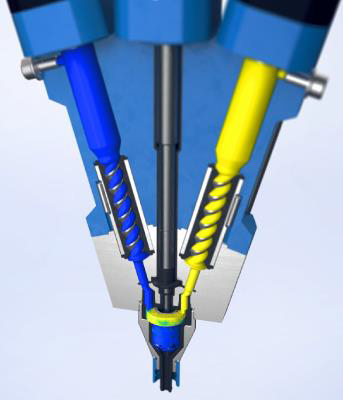

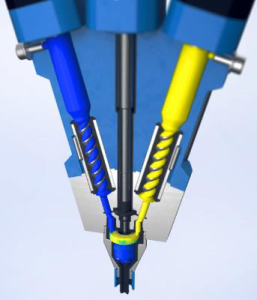

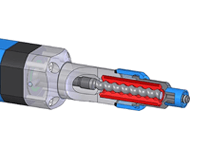

Using the same precise endless piston technology as the preeflow eco-DUO with the addition of a dynamic mixing driver, the preeflow eco-DUOMIX450 can effectively meter, mix and dispense materials, including those with differing rheologies. Through this system, the unit can homogenise two-component materials which are traditionally hard to mix, such as those with ratios up to 10:1, or materials with a significant disparity in viscosity.

By employing the use of an internal mixing motor, the eco-DUOMIX450 uses short, low volume, disposable mixing capsules rather than traditional static mixing nozzles, allowing for a more compact production process with minimal material wastage. The mixing motor is able to alleviate difficulties typically encountered when using static mixing nozzles with materials that vary in viscosity, such as back pressure requirements and homogeneity inconsistencies.

When partnered together with the eco-CONTROL EC200 DUOMIX dispensing control unit, the dispenser forms a complete package that can be integrated into any of our robotic dispensing systems or automation.

Features & Benefits

Effectively combine two-component materials which are hard to mix

Effectively combine two-component materials which are hard to mix- Minimised material wastage through compact mixing capsules

- Highly consistent and repeatable dispensing, with accuracy of ±1%, >99% of the time

- Easy system integration, including as part of our archytas series of robot integrations

- Reduced height requirements compared to static nozzle-only mixing

- Precise, controllable dosing flow

- Dynamic mixing functionality in disposable capsules for simple clean-up

Applications

The preeflow eco-DUOMIX450 is designed for precise metering, dynamic mixing, and repeatable dispensing of adhesives, sealants, coatings, inks, greases, and other fluids in applications including:

- Electronics packaging

- SMD/SMT

- Semiconductors

- LCD/LED/OLED

- Medical device assembly

- Biological chemistry

- Laboratory

- Photovoltaics

- Optics and photonics

Specifications

| Specification | |

|---|---|

| Min. dosing volume | 0.008 ml |

| Volume flow | 0.2 – 12 ml/min |

| Max. dosing pressure | 20 bar |

| Max. operating pressure | 20 bar |

| Mixing ratio | 1:1 to 10:1 |

| Max. mixer speed | 10 – 1000 rpm |

| Weight | 1,800 g |

Controller

The eco-CONTROL EC200 DUOMIX enables precise control of the eco-DUOMIX450.

Operating principle

The eco-CONTROL EC200 DUOMIX has a variety of configuration options such as dose, dispensing time, mixing motor speed and mixing ratio which can be adjusted through its intuitive graphical user interface. With its in-built memory functionality, operators can save production-related values and change them over time to suit their processes.

An integrated pressure control provides dispensing feedback to enhance the process safety of the system. Data exchange is possible with a USB interface.

Features

- Quantity program

- Start / stop program

- Time program

- Mixing ratio up to 10:1

- Adjustable mixer sizes

- Adjustable individual pot life

- Flush out or empty shot

- Manual / automatic calibration

- Mixing motor speed adjustment

- Desired-volume display in grams or millilitres

- Dispensing flow rate display in millilitres per minute or grams per minute

- Storage of PDM-supported dispensing programs

- Desired-pressure and actual-pressure display in Bar or PSI

- Digital clock

Other Information

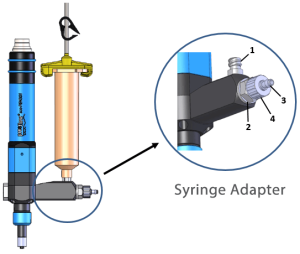

Syringe adapter with integrated bleed valve

For use in applications where the chosen material is supplied in syringe barrels, an optional adapter with an integrated bleed valve allows for direct dispensing without the risk of air bubble formation.

Made of black anodized aluminium and stainless steel, and FFKM sealing elements, the syringe adapter is compatible with almost all materials and allows for air bubble-free dispensing, even after several syringe barrel changes.

With a 1/8-inch external thread, the adapter is well suited for the eco-PEN, eco-DUO series 300, 330 and 450 and eco-DUOMIX450.

Helpful Resources

See also our Technical Articles and White papers page for the following white paper and more:

The “Endless Piston” Pump – Technology for Precision Dispensing by Peter Swanson |

Ordering Information

| Part number | Description |

|---|---|

| VIS22108 | preeflow eco-DUOMIX 450 package inc. eco-DUOMIX 450, eco-CONTROL EC200 DUOMIX, 2 x pressure sensors |

| VIS22059 | preeflow eco-DUOMIX 450 |

| VIS22035 | preeflow eco-CONTROL EC200 DUOMIX dispense controller |

| VIS22372 | preeflow eco-DUOMIX mixing capsule 1:1 to 5:1 |

| VIS22389 | preeflow eco-DUOMIX mixing capsule 5:1 to 10:1 |

| VIS20326 | preeflow eco-REMOTE 232 port for external channel selection |

| VIS21750 | Syringe adapter for eco-PEN/eco-DUO 300/330/450 and eco-DUOMIX450 |

| VIS21811 | Syringe adapter with integrated bleed valve |

Let’s start by talking about your application

- Last updated: March 2021

- Version: 1.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.