The preeflow® eco-SPRAY’s reliable, extremely precise and repeatable dosing results are finding new applications; for example, it can spray solder paste. A series of trials testing the capabilities of the preeflow eco-SPRAY for the application of solder paste had excellent results.

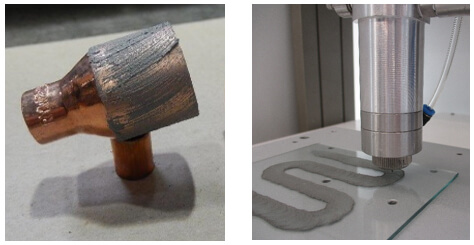

Manual application of solder paste (left) vs. eco-SPRAY (right)

Solder pastes are mixtures of solder powder and flux agents, which enable soldering of different metals and alloys. They can be highly abrasive towards dispensing equipment due to the high proportion of metal solids contained in them, and can have challenging rheologies. As a result, material and dispensing options must be carefully considered to optimise the process.

When spraying a material with a high proportion of solids, we can adjust factors such as air pressure, distance of the nozzle from the substrate and robot travel speed in order to achieve a uniform coating with a clean edge. For this specific trial, solder paste was atomised with a spraying width of 1.1 cm, and a consequent volume of 0.13 ml, with a mean deviation from the average of only 1.1%. No wear was detected to the eco-SPRAY dispensing equipment despite the abrasive nature of the paste, and it could be sprayed continuously or intermittently.

These results mean new opportunities for the application of soldering paste, with better process stability and reduced material consumption.

Categories: dispensing, soldering, spraying