Sometimes, materials are dispensed or dosed under vacuum – for example, the potting of intricate electronics assemblies may be done under vacuum in order to prevent unwanted air entrapment.

Selecting dosing equipment under this scenario might be tricky. Dispensing systems based on time/pressure can be inaccurate in changing atmospheric pressure!

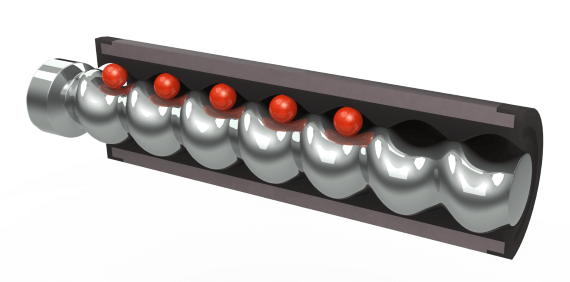

The preeflow eco-PENs and eco-DUOs have been used very successfully for this kind of application, as this case study shows. They function by using a rotor in an elastomeric stator, giving a true volumetric output based on positive displacement. Crucially, the rotor/stator system is sealed and the resulting dose is independent of the material feed pressure; and changes in atmospheric pressure. The preeflow dispensing pumps minimise incidental dripping and the preclude need for extra long dispensing needles.

Whilst the applications are still challenging for preeflow, “it turns out to be the best volumetric dosing solution for this application. Additional advantages like easy integration to automated systems and simple implementation convince in the application.”

Categories: dispensing