Stricter EU regulations on the use of hazardous substances such as lead, cadmium and mercury, will significantly impact a number of industries, possibly including the use of mercury vapour UV curing lamps in industrial printing, bonding and coating processes.

Stricter EU regulations on the use of hazardous substances such as lead, cadmium and mercury, will significantly impact a number of industries, possibly including the use of mercury vapour UV curing lamps in industrial printing, bonding and coating processes.

The full implications of the regulations need further clarification, but in the meantime many businesses are ahead of the game and have successfully adopted alternative curing technology in the shape of UV curing lamps based on LEDs. It has to be said that this has not been necessarily to achieve compliance in the face of new regulations or adopt a more environmentally-responsible stance … but for the other processing, quality and economic benefits delivered by the newer technology.

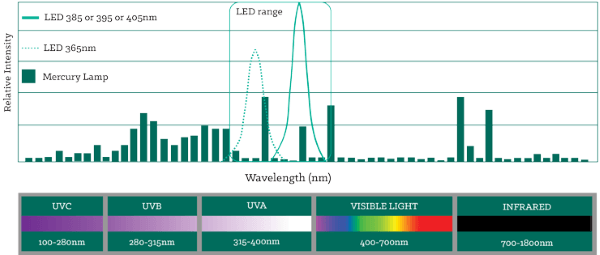

Traditional mercury arc (aka broad spectrum) lamp technology has long provided a solution to curing UV materials, enabling fast cures and therefore high throughput. However, it is not without quirks – intensity degradation during the lifetime of the lamp needs process attention, warm-up periods mean that the lamps should not be switched on and off at will, and heat and infra-red emission (whilst useful for some cures) can limit use on heat sensitive substrates.

Legislation banning mercury has been clarified in the RoHS 2 directive. But there are numerous exclusions and exemptions including the use of mercury in certain applications when no equivalent alternative technology is available. The continued use of mercury arc lamps seems to be allowable, at least in the short term, although the situation is not clear, and the writing is definitely on the wall.

Back to LED-based UV curing systems then, which offer multiple benefits including longer lifetimes, more stable output intensity, cooler curing, zero warm-up time, and reduction in power consumption.

The transition from broad spectrum mercury arc to LED requires more than investing in new equipment. LED-based UV curing lamps have narrow spectral outputs, and most existing light cure materials have been formulated to cure with the broad spectrum output of mercury arc lamps. A re-evaluation of current materials with the new LED technology is recommended, to see if material performance is still acceptable under the new cure regime; alternatively, the latest UV cure materials have been formulated to cure with both broad spectrum and narrow spectrum technologies (they might be said to be “cure agnostic”).

Categories: LED Curing, uv curing