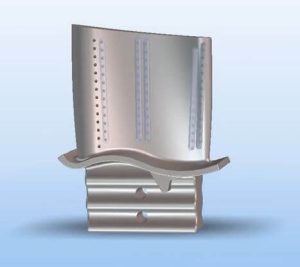

Plasma treatment of turbine blades may require effective and efficient masking of the cooling holes during the process – and something that doesn’t compromise the treatment of the surrounding surface.

Plasma treatment of turbine blades may require effective and efficient masking of the cooling holes during the process – and something that doesn’t compromise the treatment of the surrounding surface.

To achieve this, Dymax SpeedMask® temporary masking resin is applied to the cooling holes from a dispensing syringe or through a dispensing valve. The SpeedMask is cured is a few seconds by a UV/visible light-curing flood lamp. After plasma treatment, the mask is easily removed by incineration in an air or vacuum furnace, leaving a residue-free surface.

Our animated YouTube video demonstrates the masking / plasma treatment / removal process.