Polytec PU 1000 is a single part adhesive which cures quickly at room temperature to a flexible, electrically conductive polymer. It can replace traditional epoxies which are typically rigid and require high temperature cure, giving production efficiencies and enabling new applications where pliability and conductivity is important.

Polytec PU 1000 addresses applications in die attach, bonding of components in hybrid circuit applications and surface mount technology (SMT); areas where silver filled electrically conductive adhesives have been used for many decades. Usually these adhesives are epoxy-based, two-component, or premixed and frozen single-component systems. However, one significant disadvantage of epoxies is the high demand and overhead they place on the production process. The automated application of two-part adhesives requires suitable metering and mixing equipment; single-component, premixed and frozen adhesives require a sophisticated supply chain and storage to ensure an enduring temperature of at least -40°C. Another disadvantage of both these systems is the limited processing time (pot life) after mixing or thawing of the adhesive. After application, to obtain their optimum electrical and mechanical properties, traditional epoxies should be cured at elevated temperatures (typically at 120 – 150°C).

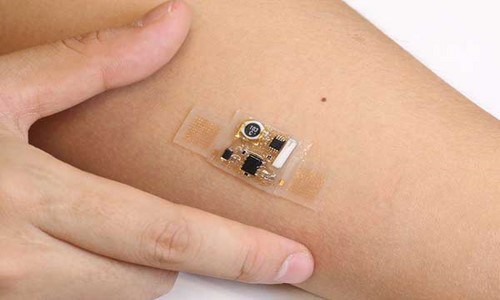

Polytec PU 1000 is a very interesting alternative to epoxy-based adhesives in various applications. It is a single-component, silver filled, paste adhesive, which can be both stored at room temperature and cured quickly at room temperature. It is flexible and elastic, which makes it ideal for bonding of flex-circuits, temperature-sensitive substrates or substrates with highly dissimilar coefficients of thermal expansion. It has found applications in smart cards and RFID circuitry, where cure can be effected in seconds. It may find interesting applications in wearable technology – clothing and accessories incorporating computer and advanced electronic technologies.

The performance of PU 1000 is considered excellent for the electrical contact of both active and passive components, especially when coupled with its ease of processing and high flexibility. The adhesive can be dispensed automatically or applied manually and has rheological properties which are particularly suitable for the requirements of jet type dispensers. It is suitable for electrically conductive bonding and coating applications on absorbing substrates like fabric, paper, leather, cork and non-absorbing substrates like glass, ceramics, PMMA, metals and most plastics.

Categories: electrically conductive, microelectronics, surface mount, wearables