We have introduced a new UV/visible light cure Form-in-Place (FIP) or Cure-in-Place (CIP) gasket material originally designed for fuel cell sealing applications. Dymax Ultra Light-Weld® GA-145 is a chemical and moisture-resistant gasket which is formulated to be tack free, yet soft and flexible, with low outgassing after cure. It can be dispensed in intricate and complex configurations with the added benefit of in-line curing which allows for increased production speed and reduced inventories. The material cures in seconds on demand, eliminating the need for racking of long-curing components and the waste associated with poorly fitting, or improper alignment of die-cut gaskets.

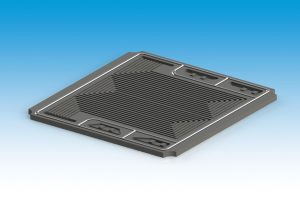

Dymax GA-145 demonstrates excellent bond strength to metals e.g. aluminium or stainless steel, also to glass and polycarbonate, and is typically used in sealing fuel cell plates and stacks, automotive door handles, appliance housings, and critical electronic assembly and device applications. This material is resistant to high-temperature and high-moisture environments while maintaining superior adhesion and flexibility. It exhibits low outgassing and low shrinkage which results in reduced stress on the fuel cell plate, stack housing, appliance housing, or electronic assembly where its translucent colour and excellent tear resistance will also be appreciated.

We have in-line or desktop station flood and spot UV light curing systems to match Dymax GA-145 requirements, to ensure fast, deep cures with maximum reliability. We have a broad range of robotic systems for dispensing FIP/CIP materials. These range from compact bench top cartesian machines, through SCARA types with a compliant articulated arm, up to gantry machines where they may be mounted over a conveyor feed.