Wire tacking for pcb track replacement or circuit modification is a long standing feature of both original equipment manufacture and refurbishment. However, the production people at Allgood Technology Ltd were not happy about the smell of acetone based accelerator fluid they need with their cyanoacrylate adhesive and urgently sought an alternative, finally settling on Flextac Tape Dots.

The Flextac system encompasses a range of sizes in pre-cut self-adhesive material which are quickly and easily applied with minimal wastage. The Dots themselves are clear and so blend into the appearance of the board unlike “instant” gels which can discolour or “bloom”. Explained Peter Allgood:

We were spurred to find another technique by the unpleasantness and perception of toxicity associated with the fumes and found the Flextac Tape Dot system with a demo video on the internet. The guys at Intertronics sent us a free sample pack which immediately solved all our problems.

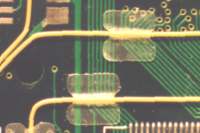

The job itself centred around a motherboard for coin counting machines which needed a length of modification wire (30 gauge wire wrap) with five tacks over its length. The job arrived at a particularly busy time so the simplicity and speed of use offered by Flextac Tape Dots was much appreciated. The team at Allgood Technology Ltd were able to rapidly evaluate the Dots from their free samples and concluded that not only were they a quicker solution but the appearance was also enhanced, at the same time any slight misalignment can easily be rectified by unpeeling and replacing.

Delighted with the outcome, Peter commented:

For us the dots were a complete solution in a box. We got rid of some nuisance problems while we improved our process and the quality of our end result.

Categories: electronics, rework and repair