Wire Tape Dots, PCB Wire Tacking Adhesives

About Wire Tape Dots, PCB Wire Tacking Adhesives

Wire Tape Dots make the job of bonding jumper wires neat and fast. They are a wire tacking system consisting of pre-cut shapes of a thin, flexible polymer film coated on one side with a high performance, electronics grade permanent pressure-sensitive adhesive. The result is a highly conformable, high strength bond.

Wire Tape Dots will hold secure after exposure to numerous chemicals including cleaning solutions/sprays, saponifiers, mild acids and alkalies, and will hold secure through a typical circuit board hot water wash.

Features & Benefits

- Very good initial bond strength that increases over 72 hours to stabilize as a high strength reliable bond

- High humidity has a minimal effect on adhesive performance

- Will hold securely after exposure to numerous chemicals including cleaning solutions/sprays, saponifiers, mild acids and alkalies

- Wires will hold securely through a typical PCB hot water wash

- Can be repositioned during and immediately after initial bonding without causing adhesive transfer or loss of bond strength

- Retains its performance and properties for one year from date of purchase when stored at room temperature

Applications

- Bonding jumper wires used for modifications

- Bonding jumper wires used for conductor repairs

Specifications

- Temperature Cycling and Bond Strength

Bond strength generally increases after four times through:

4 hours at 70°C

4 hours at -29°C

16 hours at room temperature - Temperature Range

Low: -40°C

High short term: 200°C

High long term: 135°C

Thermal Properties

| Property | Typical value | Test method |

|---|---|---|

| Peel strength 72 hrs at 22°C | 84 oz/in | ASTM D3330 Modified |

| Static shear strength 22°C/1000g | >10,000 min | ASTM D3654 |

| Tensile strength (yield) 22°C | >2600 psi | ASTM D2370 |

| Elongation | 100% | ASTM D2370 |

| Thermal conductivity | 0.17 w/m-K | ASTM C518 |

| Coefficient of thermal expansion | 5.5 x 10-4 m/m/C | ASTM D696 25-175C |

Electrical Properties

| Property | Typical value | Test method |

|---|---|---|

| Dielectric strength | 1700 volts/thou | ASTM D149 |

| Dielectric constant 25°C, 1 kHz | 3.4 | ASTM D150 |

| Dissipation factor 25°C, 1 kHz | 0.018 | ASTM D150 |

| Surface resistivity – Adhesive layer | >1 x 1014 ohm/square | ASTM D257 |

| Surface resistivity – Polymer film layer | >1 x 1016 ohm/square | ASTM D257 |

| Volume resistivity – Adhesive layer | >1 x 1015 ohm/cm | ASTM D257 |

| Volume resistivity – Polymer film layer | >1 x 1018 ohm/cm | ASTM D257 |

| Insulation/moisture resistance – Adhesive layer | >1 x 1011 ohm | MIL-I-46058C (100 VDC 60 sec) |

| Insulation/moisture resistance – Polymer film layer | >1 x 1012 ohm | MIL-I-46058C (100 VDC 60 sec) |

| Voltage breakdown | 3500 volts | – |

Other Information

Our Technical Bulletins page has links to:

- Technical Bulletin: Wire Tacking – The Options

Ordering Information

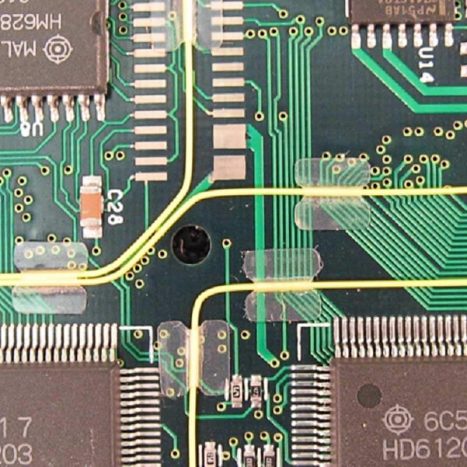

Illustration shows wire tape dots bonding 30 gauge jumper wire:

6.5mm round

6.5mm square

Illustration shows wire tape dots bonding (3) 30 gauge jumper wire:

10.0 mm round

10.0 mm square

| Part number | Description | Pack Size |

|---|---|---|

| CRC310-2100 | Wire Tape Dots – variety pack | 370 |

| CRC310-0651 | Wire Tape Dots – 6.5 mm round | 370 |

| CRC310-0652 | Wire Tape Dots – 6.5 mm square | 450 |

| CRC310-1001 | Wire Tape Dots – 10.0 mm round | 210 |

| CRC310-1002 | Wire Tape Dots – 10.0 mm square | 210 |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 4.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.