Dymax 9200-W Series UV Adhesives for Consumer Wearable Electronics

About Dymax 9200-W Series UV Adhesives for Consumer Wearable Electronics

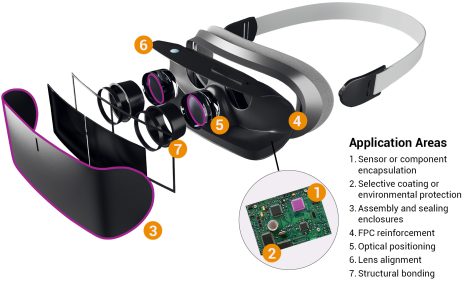

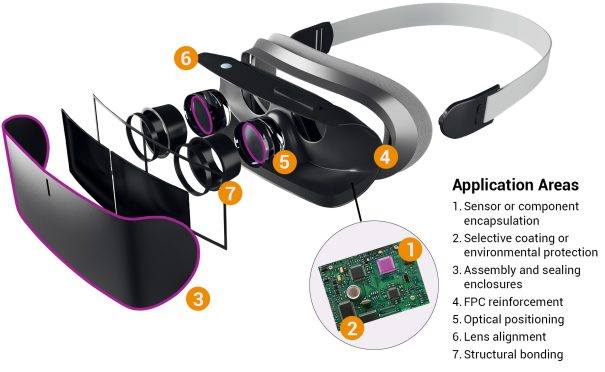

The Dymax 9200-W series of wearable device adhesives and encapsulants cure in seconds on exposure to ultraviolet light and/or visible light, enabling greater throughput and reduced processing costs. Materials in the range have been specifically formulated for wearable consumer electronic devices where materials of concern and their proximity to skin matter.

The Dymax 9200-W series has been developed without isobornyl acrylate (IBOA), a common skin irritant. They are made with low-sensitising ingredients for applications which are touching, or near the skin, such as smartwatches, fitness trackers, VR headsets or goggles, earbuds and headphones – or where devices cannot be hermetically sealed.

The series of adhesives and encapsulants are made of 100% solids to ensure no solvents are released during application and curing, eliminating the need for solvent handling, while enhancing worker safety and minimising environmental impact.

If you are interested in ISO 10993 accredited adhesives for wearable medical devices, Dymax 2000-MW series are available.

Features & Benefits

- Formulated without IBOA

- Cures on demand, in seconds, with UV and/or visible light

- Grades available with a secondary moisture cure for applications with shadowed areas

- 100% solids, 100% solvent-free, single-part materials

- Low sensitising formulation for skin contact applications

Applications

- Optical alignment and lens positioning

- Assembly bonding and sealing

- Electronics encapsulation

- Wire and flex tacking

- Structural bonding

Selector Guide

| Adhesive | Typical Application | Substrates |

|---|---|---|

| Dymax 9201-W DYM9201-W |

Dymax 9201-W is a medium viscosity light curable encapsulant that bonds using LED or broad spectrum UV light. It has a secondary moisture cure for applications with shadowed areas. Suited for applications such as encapsulating wire bonds, chip-on-board, or chip-on-flex circuits. 9201-W provides electrical insulation, chemical, and environmental protection, as well as superior protection through reliability testing such as thermal shock, cycling, and vibration. | ABS, FR4,PA, PI, PET, TPU |

| Dymax 9202-W DYM9202-W |

Dymax 9202-W is a high-viscosity LED or broad-spectrum UV curing adhesive designed for optical alignment applications and lens positioning where low shrinkage and high viscosity are essential for precision placement. Containing no known skin sensitisers, such as IBOA, 9202-W is suitable for wearable devices which are touching or near the skin, such as smartwatches, VR headsets and headphones. | PC, PMMA, PET, Glass, SS |

| Dymax 9210-W DYM9210-W |

Dymax 9210-W is a medium viscosity encapsulant for FPC reinforcement, selective coating, and component encapsulation applications in consumer wearable devices. 9201-W cures with LED and broad-spectrum UV light, and features a secondary moisture cure for shadowed areas. The material exhibits great performance in reliability testing and bonds well to typical electronic substrates, including polyimide, polyamide, and FR4. | FR4, PA, PI |

| Dymax 9211-W DYM9211-W |

Dymax 9211-W is a low-stress plastic bonding adhesive which cures with UV/Visible light energy for ultra-fast bonding and sealing of camera module components found in consumer wearable devices. It forms excellent bonds to PC, LCP, ABS, and FR4 substrates and is specifically designed for CCM applications and camera module barrel fixtures. Halogen free. | ABS, FR4, LCP, PA6, PC, PET, PETG, PI, PU, TPU |

- Last updated: June 2023

- Version: 1.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.