The job of a thermal paste is to ensure really good heat transfer between a device (e.g. microprocessor, power component) to a heat sink – perhaps through adverse conditions or large operating temperature ranges. It can only do this job if it is applied evenly and to a specified thickness, without air entrapment or material voids – poor application can result in poor thermal performance.

Good thermal conductivity would imply that the paste is quite highly filled with a conductive filler, which can make dispensing a bit of a challenge – doubly so if the material is a two part (2k) system which has to be metered and mixed before application. The mixed material can be quite viscous and difficult to apply accurately. Any wastage generated from the application process can be costly, as these are not inexpensive products.

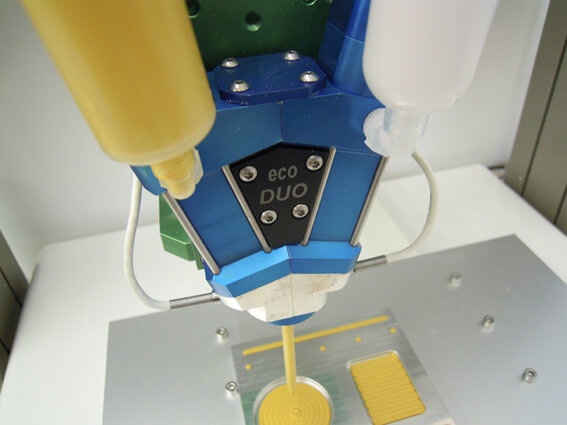

The preeflow eco-DUO 450 can be a really good solution to these challenges, providing metering, mixing and dispensing to high levels of accuracy and repeatability. We have uploaded a new video showing the eco-DUO 450 in action on a dispensing robot, which shows its performance with a two part thermal paste.

Categories: dispensing, mixing, thermally conductive