These days, you can find microcapsules in almost every industrial sector, where they take numerous roles. In adhesive technology, microcapsules can fulfill several functions. For example, microcapsules may be an integral part of the control of reaction and curing processes. Some anaerobic “threadlocking” adhesives contain microcapsules. After applying the adhesive to a screw, the action of screwing it into a thread bursts the capsules, releasing active materials which initiate the cure.

Microcapsules can also act as spacers; including them in an adhesive will result in a predetermined minimum bondline thickness between two substrates. Some adhesives have very high levels of fillers to give thermal conductivity or other desirable properties.

The handling, application and dosing of these materials can give you some big challenges. The material feed and dispensing onto the substrate must occur without any shear stress to prevent damage to the microcapsules. Consequently, piston pumps may not be appropriate if they induce high pressure (perhaps over 100 psi) or pulsation which can harm the microcapsules. Gear pumps might not work either, because of the geometry involving physical interaction with the gears and high shear forces. Systems based on pinch valves, hose pumps or diaphragm pumps may be suitable to test, although the pulsating action and the level of accuracy are things to consider.

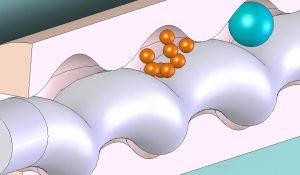

An ideal dosing system must impart no shear stress on the material, and be highly precise. Technology based on the endless-piston-principle from ViscoTec GmbH offers these features. preeflow positive displacement, volumetric dispensing pumps will dispense or dose independent of input pressure, material viscosity and ambient temperature. The special geometry of the stator and rotor configuration works as a progressive cavity pump. The rotor seals against the stator, forming a series of spaces or pockets, which translate along as the rotor rotates, keeping their form and volume. The pumped material is moved inside the pockets. In addition, the pockets are shaped such that they taper and overlap; the output is continuous, even and non-pulsing. Therefore it is possible to dose very shear sensitive and delicate materials without damaging them.

preeflow dispensers are an excellent solution for micro-dispensing. With accuracy of ± 1% and repeatability > 99 %, this technology should be considered for the pumping, feeding and dosing of fluids which contain microcapsules.

Categories: dispensing