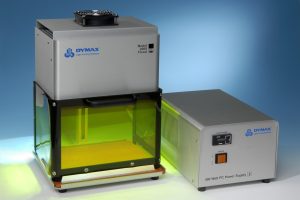

As specialists in the field, we make no apology for keep banging on about the advantages of UV curing for adhesives, coatings and inks in the automotive, electronic, optical and medical device assembly industries, where it can greatly speed production cycles, enhance quality and reduce piece part cost. And investment in equipment doesn’t need to be a hurdle: the DYMAX 2000-PC lamp is a low cost entry level genuinely intense UV curing flood lamp. Applications include UV bonding, sealing and encapsulating.

The DYMAX 2000-PC features 75mW/cm² intensity over a 200x200mm working area and will get users on the ladder of UV curing benefits, including single-part dispensing and fast cure speeds in the region of seconds rather than hours, with no mess, for a minimal investment.

Bulb life on the DYMAX 2000-PC (400W metal halide) is warranted for 2000 hours and there are a range of accessories including mounting stands and shutters which may be retro-fitted. Lamps are offered for demonstrations and trials at our Technology Centre in Oxfordshire.

Categories: uv curing