Wondermask© P Peelable Temporary Solder Mask

TEC 2211

About Wondermask© P Peelable Temporary Solder Mask

Also available to buy online at ![]()

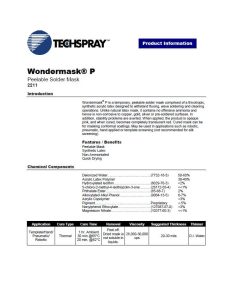

Techspray TEC2211 Wondermask© P is a temporary, peelable solder mask or resist composed of a thixotropic, synthetic acrylic latex designed to withstand fluxing, wave soldering, and cleaning operations. Unlike natural latex mask, it contains no offensive ammonia and hence is non-corrosive to copper, gold, silver, or pre-soldered surfaces and will not stain substrates. Material stability problems, common in natural latex formulations, are avoided. When applied, the product appears opaque pink, and when cured, becomes completely translucent red. Cured mask can be used in water or solvent systems and in masking for conformal coatings. Excellent heat stability allows for prolonged exposure to high temperature without product degradation. This product may be used in most common forms of mask applications such as robotic, pneumatic, hand applied, or template screening (not recommended for silk screening).

Features & Benefits

- Insoluble in water or solvent

- Contains no ammonia

- No offensive odour

- Colour change on drying

- Static safe – non-tribo charging

- Stable formulation

- Long shelf life

- Non-corrosive

- Safe on metals

- Thixotropic

- Versatile

Applications

Protects plated through holes and contact surfaces from solder during soldering operations

Protects plated through holes and contact surfaces from solder during soldering operations- Mask areas during conformal coating applications

- Gold fingers

- Card edges

Directions for Use

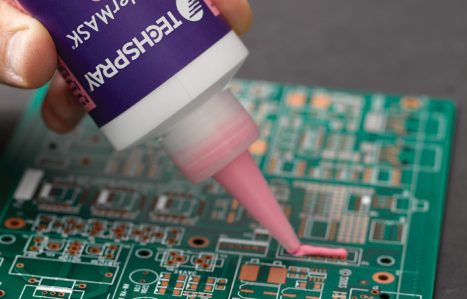

- Mask can be applied using robotic, pneumatic, hand applicators or template screening.

- Not recommended for silk screening applications.

- Apply a 0.75mm to 1mm coating for best results to desired area.

- Wondermask P may be thinned using deionised water.

- The substrate should be free from grease, oil, and particulate matter.

- Drying times depend upon ambient humidity. Under normal conditions Wondermask P will cure in 1 hour at 25°C; however, cure can be accelerated to 30 minutes at 65°C or 20 minutes at 82°C.

- Do not over cure as blistering of mask can occur causing removal problems.

- Mask will change from an opaque pink to a translucent red when complete cure is accomplished.

- Mask does not have to be completely dry to withstand soldering operation; however, it should be completely translucent before removal. Removal is by peeling off.

- Dried mask is not soluble in water or solvents.

Ordering Information

| Part number | Description | |

|---|---|---|

| TEC2211-8SQ |

Wondermask P – 8 fluid ounce squeeze bottle |  |

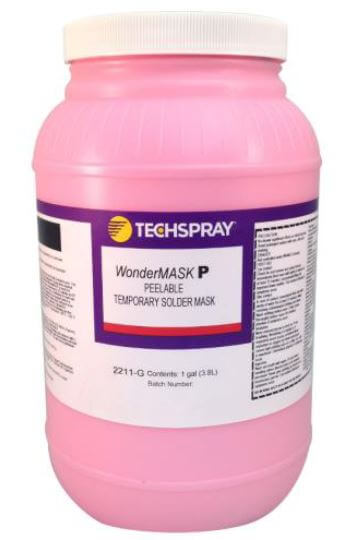

| TEC2211-G |

Wondermask P – 1 US gallon in plastic |  |

| TEC1715-30CC |

Wondermask P – 5 x filled 30ml barrels |  |

Let’s start by talking about your application

- Last updated: January 2024

- Version: 4.7

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.