PlasmaBrush PB3 Plasma Surface Treatment System

About PlasmaBrush PB3 Plasma Surface Treatment System

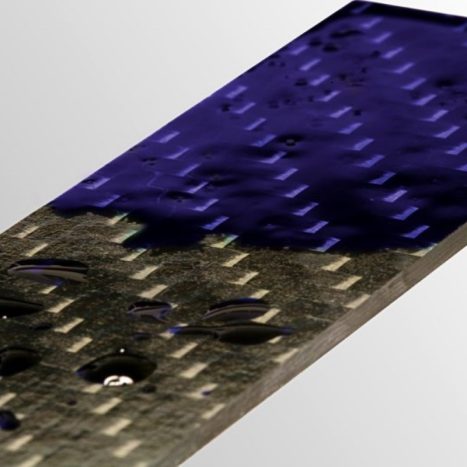

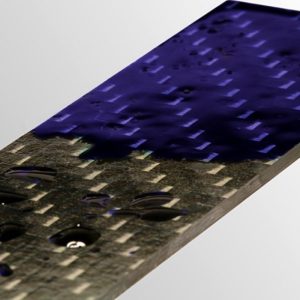

Relyon Plasma surface treatment products improve adhesion and wetting of surfaces which are otherwise difficult to bond or print on. Plasma surface treatment is both highly efficient and environmentally friendly, and the bulk properties of the treated part are not altered. The surface does not suffer marks or discolouration.

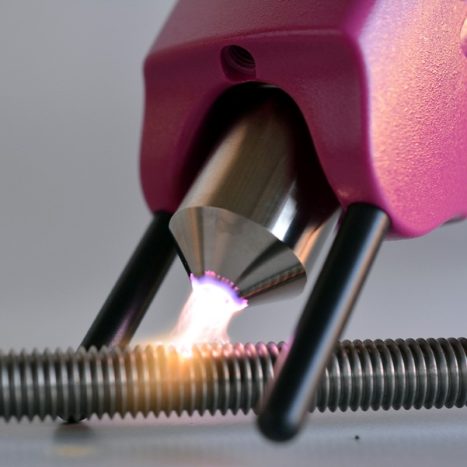

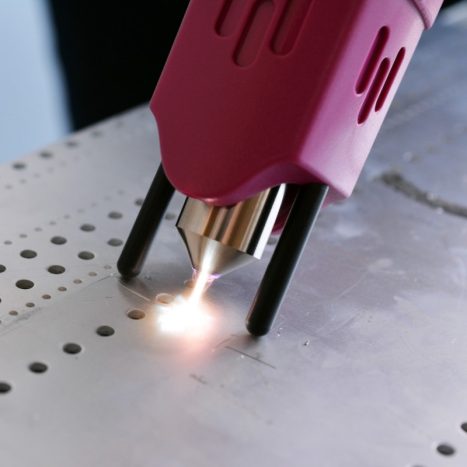

The PlasmaBrush PB3 is designed for integration into automated manufacturing processes. The lightweight and compact head can be easily mounted on a robot. The PlasmaBrush uses air supply to operate, but can also be used with noble gases where required. Typical applications for the PlasmaBrush include:

Pre-activation for bonding, sealing, casting or printing

Pre-activation for bonding, sealing, casting or printing- Coating, laminating and sealing

- Ultrafine cleaning

- Reduction of oxide layers

- Surface functionalization

- Germ reduction and sterilization

The PlasmaBrush PB3 system meets the requirements of the independent communications industrial standard CANopen®. The PS2000 power source for the PlasmaBrush can be controlled with a simple DIP switch.

A complete workstation package is available, comprising the PlasmaBrush PB3 mounted on a robot with enclosure and extraction unit.

For more information on how plasma surface treatment can improve bonding, watch our video on YouTube.

CANopen® is a registered trademark of CAN in Automation (CiA) GmbH.

Features & Benefits

- Improves adhesion & wetting

- Efficient and environmentally friendly

- Head can be easily mounted on a robot

Applications

- Medical

Plasmabrush PB3 Workstation Filters, cell wells, test tubes, catheters, syringes, petri-dishes, needle hubs, lenses

- Automotive

Fuse covers, engine parts, air bag covers, rubber profiles, tubing, headlights - Electronics

Cable, switches, polyester pcb’s, housings & enclosures, screens - Consumer

Irons, blenders, shakers, measuring containers - Food, cosmetics & drug

Bottles, caps, jars, tubes

Relyon Plasma systems can be incorporated into existing or new production lines, and supplied as semi to fully automated systems or as a stand alone workstation.

Other Information

Find out more about the technology behind the PB3 by reading our technical bulletins and white papers:

Ordering Information

| Part number | Description |

|---|---|

| REL78879101 | Relyon Plasma PlasmaBrush PB3 – plasma generator PG-31 with 1m cable |

| REL78879601 | Relyon Plasma PlasmaBrush PB3 – generator connecting cable, HVC high voltage, 9m |

| REL79120002 | Relyon Plasma PlasmaBrush PB3 – PS 2000 power source, 19″ wide with display |

| REL1000603600 | Relyon Plasma PlasmaBrush PB3 – PS 2000 emergency stop switch |

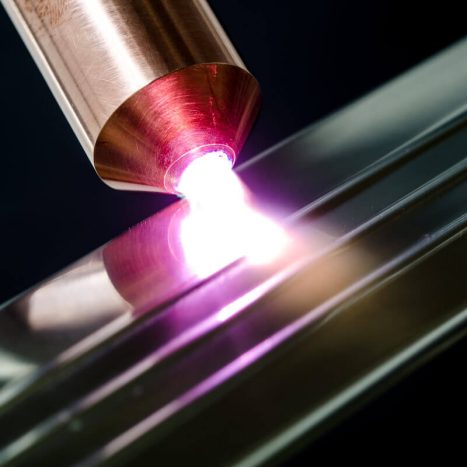

| REL1000242500 | Relyon Plasma PlasmaBrush PB3 – nozzle A250 for temperature-sensitive surfaces, copper |

| REL1000600700 | Relyon Plasma PlasmaBrush PB3 – nozzle A350, middle power density, copper |

| REL78707200 | Relyon Plasma PlasmaBrush PB3 – nozzle A450, high power density, copper |

| REL1000605400 | Relyon Plasma PlasmaBrush PB3 – digital I/O communication package |

| REL1000603700 | Relyon Plasma PlasmaBrush PB3 Starter Kit G – gas supply package, includes power supply, air preparation, solenoid, cables and hose |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 2.5

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.