Effective, easy and affordable plasma surface treatment

Improve your adhesion

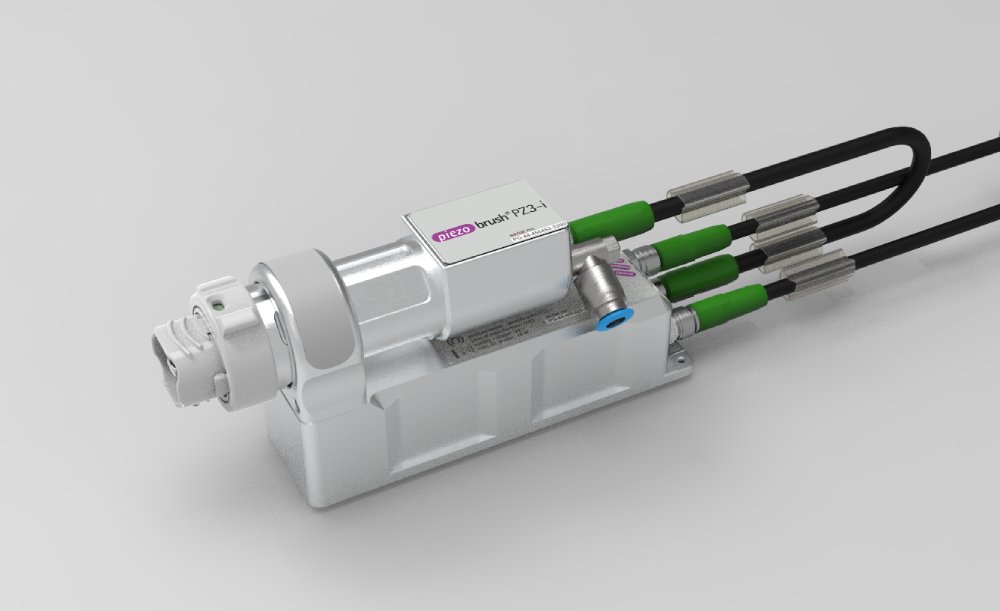

The handheld and mountable piezobrush PZ3 and PZ3-i from Relyon Plasma deliver simple, safe and intuitive plasma surface treatment to plastics, glass, ceramics, metals, semiconductors, natural fibres and composite materials.

Improve your adhesion

Boost the adhesion and wetting properties of your difficult to bond substrates by altering its surface energy.

Safe for temperature-sensitive components

Generating cold-active plasma at temperatures less than 50°C enables the PZ3 to treat even your temperature-sensitive substrates.

Clean surface contamination

As well as boosting adhesion, plasma treatment removes organic, inorganic, and microbial surface contamination, making surfaces ultra-clean. It also has the added benefit of removing odours from substrates.

Easy to use plasma treatment

Requiring no specialist technical knowledge to operate, the PZ3 series of surface treatment devices are equipped with several process control features to allow you to tailor the output to suit your application.

Do away with chemical primers

The piezobrush PZ3 delivers plasma surface treatment in a safer format to alternatives such as chemical primers, flame treatment processes or mechanical roughening, reducing your process health and safety concerns, whilst achieving your desired results.

Start along the path to strong, reliable bonds

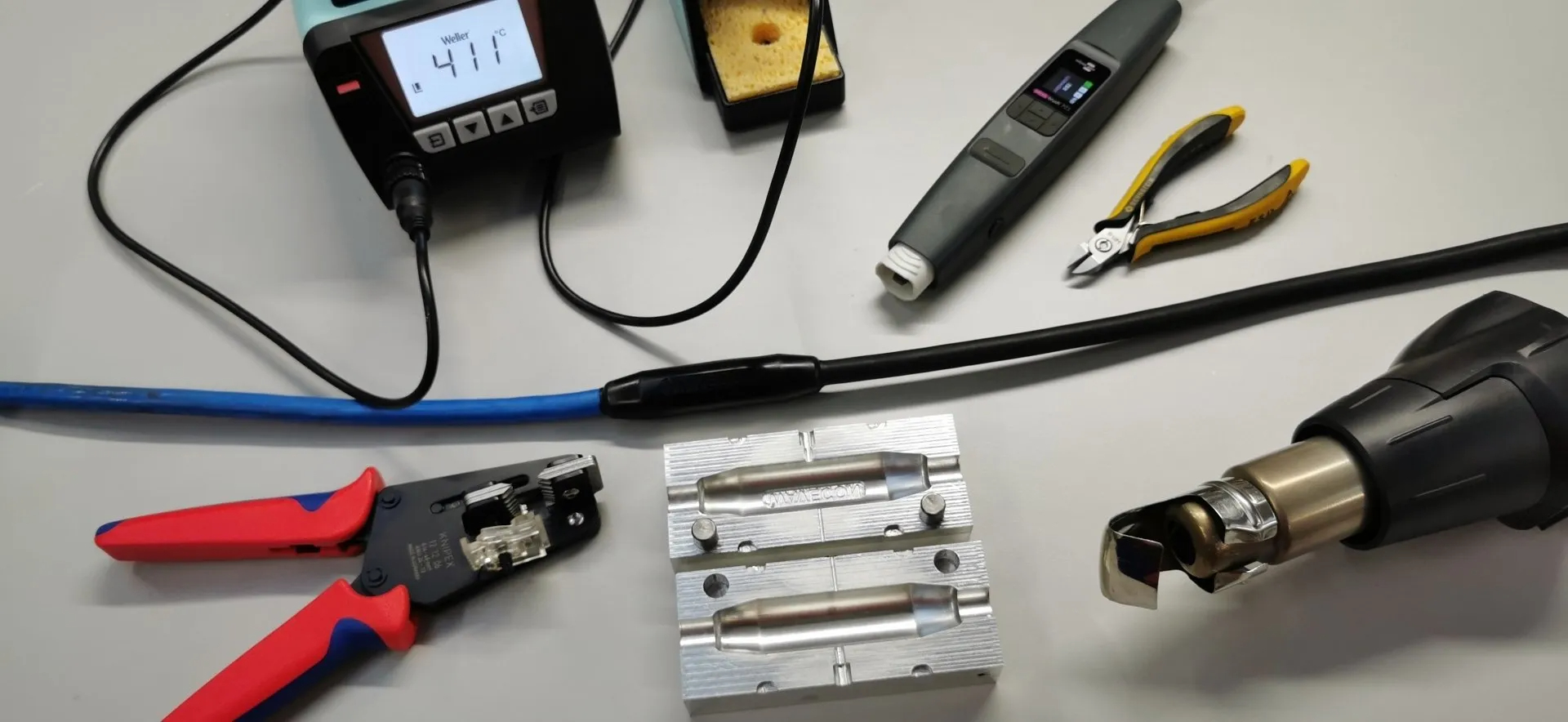

Plasma surface treament equipment is available for as little as £2500. Units expand the possibilities of bonding applications, allowing utilisation of more difficult to bond substrates such as plastics and glass. Have a look at our range of piezobrush plasma surface treatment tools:

See how our customers achieved their production goals with plasma surface treatment:

|

Plasma technology for surface cleaningThis white paper devles into how organic, inorganic and microbial surface contaminants can be removed from surfaces using cold atmospheric pressure plasma and the advantages of doing so.

|

|

Cold plasma in the electronics industryBased on real world applications, this white paper discusses the potential benefits derived from implementing cold plasma surface treatment prior to a bonding, coating, or printing process.

|