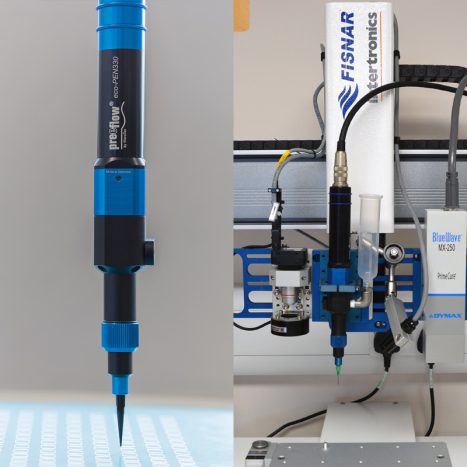

preeflow® eco-PEN Precision Volumetric Dosing Pump, for Highly Accurate Repeatable Dispensing

About preeflow® eco-PEN Precision Volumetric Dosing Pump, for Highly Accurate Repeatable Dispensing

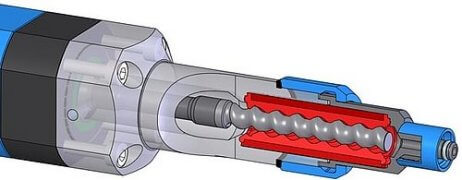

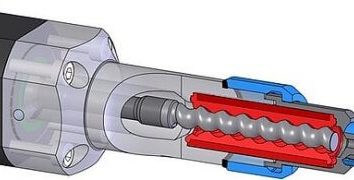

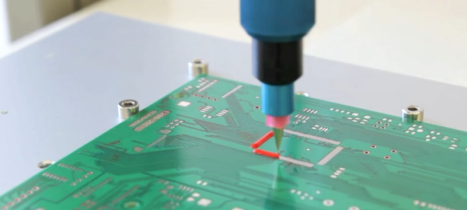

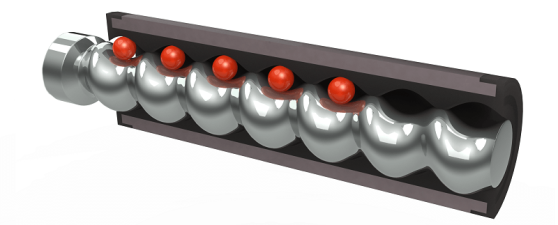

The preeflow eco-PEN is a precision volumetric, positive displacement, dosing/dispensing system that gives you accuracy and repeatability by means of a rotor which turns inside a stator. The preeflow eco-PEN uses a progressive cavity pump principle which doses and dispenses a wide range of material viscosities with no stress to the material, and absolute control.

preeflow eco-PENs can be integrated into any of our robotic dispensing systems. The preeflow eco-PEN delivers optimum results when used with Preci-Tips Precision Dispensing Tips.

Features & Benefits

- Precise, process-stable dispensing as small as 0.001ml (1μl)

- Highly repeatable and consistent dispensing, with an accuracy of ±1%, >99% of the time

- Gentle product dosing process using positive displacement

- Linearly proportional control characteristics

- Wide control and application range

- Controlled reverse flow and clean product break

- Easy system integration, including as part of our archytas series of robot integrations

Applications

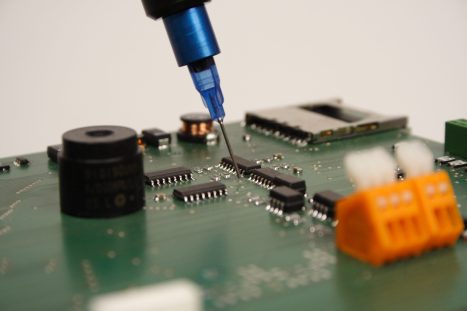

The preeflow eco-PEN is designed for dot-dispensing, bead application with dispensing rate adjustable to the run speed, and encapsulation applications for:

- Electronics packaging

- SMD/SMT

- Semiconductor

- LCD/LED

- Medical device assembly

- Biological chemistry

- Laboratory

- Photovoltaic

- Optics and photonics

Controllers

The eco-CONTROL EC200 2.0 control system provides total control of preeflow volumetric valves during the dispensing process. It’s designed for either benchtop or rack-mounted location, dependent on the model.

Operating principle

The unit is operated via a bright, 7” touch screen, making it simple to use. External signals can be connected via I/O ports to a PLC for control in automated lines. Up to 100 dosing programs, with part management can be stored locally.

Error messages for filling level and motor current are also monitored (an RS232 interface is provided).

It is possible to control two eco-PEN precision volume dosing units (as a factory-fit option).

Features

- Quantity and start/stop program

- Set-volume readout in g or ml

- Dosing flow readout in ml/min and g/min

- Storage of up to 100 dosing programs with part management

- Set pressure and actual pressure readings in bar/psi

Selector Guide

| Model | Smallest dose | Adjust flow rate | Weight |

|---|---|---|---|

| eco-PEN XS 180 | 0.00025 ml (0.25μl) | 0.0044 – 0.35 ml/min | 175g |

| eco-PEN300 | 0.001 ml (1μl) | 0.12 – 1.48 ml/min | 280g |

| eco-PEN330 | 0.002 ml (2μl) | 0.2 – 3.30 ml/min | 300g |

| eco-PEN450 | 0.004 ml (4μl) | 0.5 – 6.00 ml/min | 300g |

| eco-PEN600 | 0.015 ml (15μl) | 1.4 – 16.00 ml/min | 650g |

| eco-PEN700 | 0.060 ml (60μl) | 5.3 – 60.00 ml/min | 650g |

| eco-DUO330 For two part formulations |

0.005 ml (5μl) | 0.1 – 6.60 ml/min | 1230g |

| eco-DUO450 For two part formulations |

0.010 ml (10μl) | 0.2 – 12.00 ml/min | 1230g |

| eco-DUO600 For two part formulations |

0.030 ml (30μl) | 0.6 – 32.00 ml/min | 1880g |

Other Information

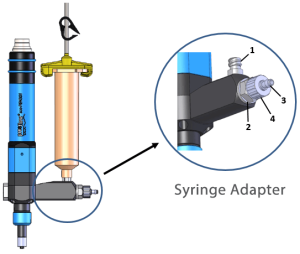

Syringe adapter with integrated bleed valve

For use in applications where the chosen material is supplied in syringe barrels, an optional adapter with an integrated bleed valve allows for direct dispensing without the risk of air bubble formation.

Made of black anodized aluminium and stainless steel, and FFKM sealing elements, the syringe adapter is compatible with almost all materials and allows for air bubble-free dispensing, even after several syringe barrel changes.

With a 1/8-inch external thread, the adapter is well suited for the eco-PEN, eco-DUO series 300, 330 and 450 and eco-DUOMIX450.

Self-sealing rotor/stator design

See also our Technical Articles and White papers page to download “The “Endless Piston” Pump – Technology for Precision Dispensing” – a whitepaper about this technology.

Stainless Steel Housing Kit

For applications which require the dispensing of aggressive materials such as solvents or plasticisers or abrasive compounds, a stainless steel housing kit is available. Offering improved resistance to fluxes and oxidants as well as organic and inorganic acids below pH4, the robust design of the steel kit extends the lifetime of the eco-PEN 300 and 450, whilst maintaining the accuracy and repeatability of the unit.

Hardwearing by design, the housing kit can withstand repeated cleaning making it suitable for applications carried out within a cleanroom environment.

Set-up and maintenance

Setting up your eco-PEN is fast and straightforward. preeflow have put together an easy to follow video which will guide you during your first set up.

For information on how to maintain and clean your eco-PEN watch preeflows video tutorial.

Case studies

See the preeflow eco-PEN as part of a real application in these dispensing and robotics Case Studies:

|

Automated dispensing helps security manufacturer increase throughput and quality

GJD Manufacturing switched to an automated method of dispensing silicone for sealing a plastic lens to aluminium housing. By doing this, they improved the throughput and quality of their white-light and infra-red LED illuminators for the security industry. |

|

Precision dispensing helps electrical manufacturer to reduce waste by improving quality and yield

By switching to an automated dispensing system, this electrical manufacturer reduced scrappage and therefore improved quality and yield of their product. |

All Downloads

Ordering Information

| Part number | Description |

|---|---|

| VIS20505 | preeflow eco-PEN300 |

| VIS21529 | preeflow eco-PEN330 |

| VIS20092 | preeflow eco-PEN450 |

| VIS20048 | preeflow eco-PEN600 |

| VIS20723 | preeflow eco-PEN700 |

| VIS21529 | preeflow eco-DUO330 |

| VIS20639 | preeflow eco-DUO450 |

| VIS21175 | preeflow eco-DUO600 |

| VIS22402 | preeflow eco-CONTROL EC200-2.0 |

| VIS20326 | preeflow eco-REMOTE 232 port for external channel selection |

| VIS20143 | preeflow eco-PEN stand |

| VIS20145 | preeflow holder for eco-PEN 300/450 |

| VIS21750 | Syringe adapter for eco-PEN and eco-DUO 300/330/450 |

| VIS21811 | Syringe adapter with integrated bleed valve |

Let’s start by talking about your application

- Last updated: November 2022

- Version: 9.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.