Opti-tec 5053-F-B High Temperature Fast Cure Epoxy Adhesive for Fibre Optic Terminating

OPT 5053-F-B

About Opti-tec 5053-F-B High Temperature Fast Cure Epoxy Adhesive for Fibre Optic Terminating

Also available to buy online at ![]()

Opti-tec 5053-F-B is a two-component, low viscosity, heat curing epoxy designed for high-temperature applications. It is especially well suited to fibre optic terminating, where optical fibres are “pot and polished” into connectors or ferrules.

Opti-tec 5053-F-B is an improved and fast cure version of Opti-tec 5053.

Features & Benefits

- High surface energy and low viscosity allows it to readily wet and wick between optical fibres. It develops strong adhesion to most materials used in fibre optics and optics, including metals, ceramics, glass and most plastics.

- High glass transition temperature results in excellent high temperature performance and creep resistance

- Resists moisture, vapours and most chemicals. It features low outgassing and low vapour pressure, making it an ideal sealing material for electronic and optical applications.

- Colour change upon cure, going from clear to deep translucent red.

- Specially formulated to have very low skin sensitivity

- Long pot life and good handling characteristics

- Used for Telcordia GR-326-CORE compliant assemblies (General Requirements for Singlemode Optical Connectors and Jumper Assemblies – formerly Bellcore), where its high Tg and environmental robustness allow the termination to meet the specification. Note: optimal cure schedule required.

Applications

- Fibre optic terminating

- Endoscope manufacture and repair

- Optoelectronics

- High temperature, high performance bonding

- Electronic sealing

Specifications

Part number change: as of version 5.0, April 2021, the part number of this product changed from Opti-tec 5053-F-A to Opti-tec 5053-F-B. This is due to an unavoidable change in a formulation component. This change does not affect the product data-sheet specifications. The new formulation has passed internal testing and is deemed to be equivalent.

| Specification | ||

|---|---|---|

| Mix ratio | 8:1 resin to hardener | |

| Mix viscosity | 500-2,000 cps | |

| Surface tension | 42-44 mN/m | |

| Pot life | 4 hours @ 23°C (4g mixed) |

|

| Cure schedule | Bondline temperature 85°C 105°C 125°C |

Time 15 mins 5 mins 2 mins |

| Note: Optimal cured properties are achieved by curing for 5 minutes at a bondline temperature of 120°C. Whilst lower cure temperatures are quoted, they are not recommended for best performance. | ||

| Optimum cured properties (5 minutes @ 120°C) |

||

| Refractive index | 1.55 | |

| Glass transition temperature (Tg) | >100°C | |

| Specific gravity | 1.15 | |

| Hardness, Shore D | 85 | |

| Temperature range | -60 to 200°C | |

| Modulus of elasticity | 1 GPa | |

| CTE | 55 ppm/°C Average between 0°C and 100°C |

|

| Adhesive properties | ||

| Lap shear (Al/Al) | 11 MPa (@ 23°C) | |

| Shelf life | 12 months from date of manufacture in original sealed containers | |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

See how the Opti-tec 5053-F-B works as part of a real application in this adhesive Case Study:

|

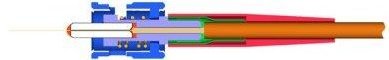

Fiber optic lighting potting

Unitising of common end fibre optic lighting harnesses using Opti-tec 5053-F-B. |

Our Technical Bulletins page has links to:

- Technical Bulletin: Operator Sensitisation from Fibre Optic Epoxies

Ordering Information

OPT 5053-F-B is available in twinpacks or in bulk.

The twinpack is a clear film sachet, with the resin and hardener separated by a removable clip and rail divider. Click here for instructions on how to mix twinpacks.

Standard twinpack size is 4g total weight. OPT 5053-F-B twinpack sachets are packaged in quantities of 5, sealed into a protective aluminium foil pouch.

| Part number | Description |

|---|---|

| OPT5053-F-B-4G |

5 x 4g twinpack sachets |

| OPT5053-F-B-450G |

450g kit |

| OPT5053-F-B-900G |

900g kit |

For optimal results, store away from acids, amines, strong alkalis and oxidising material. Static electricity and formation of sparks must be prevented. Keep only in the original container. Keep container tightly closed and upright, in a cool, well-ventilated place. Protect containers from damage. Bund storage facilities to prevent soil and water pollution in the event of spillage. The storage area floor should be leak-tight, jointless and not absorbent.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 5.4

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.