Clear Pressure Pot Reservoirs

About Clear Pressure Pot Reservoirs

IDM Clear Pressure Pot Reservoirs are used in the controlled dispensing of lower viscosity adhesives, coatings, and various other liquids. These pressure pots are well-suited for a range of liquids and fluids, including cyanoacrylate adhesives (CAs), solvents, anaerobic adhesives, UV adhesives, and similar low-viscosity liquids that are typically packaged in bottles, jars or pails of up to 10 liters.

IDM Clear Pressure Pot Reservoirs are used in the controlled dispensing of lower viscosity adhesives, coatings, and various other liquids. These pressure pots are well-suited for a range of liquids and fluids, including cyanoacrylate adhesives (CAs), solvents, anaerobic adhesives, UV adhesives, and similar low-viscosity liquids that are typically packaged in bottles, jars or pails of up to 10 liters.

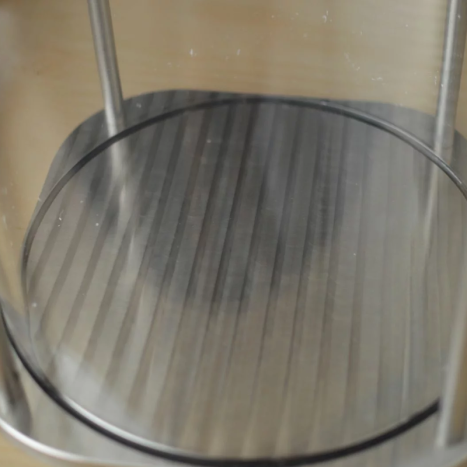

Made of clear toughened glass and stainless steel, these pressure pots enable operators to make easy visual checks of materials levels during operation, without the need to de-pressure the equipment to look inside, saving time.

By using regulated air pressure, materials are feed from their containers through disposable tubes to a dispensing valve or dispensing pen, for precise and controlled application.

For added functionality, some versions of the IDM Clear Pressure Pot, known as the IDMPPCTGEL models, come equipped with electrically powered agitation systems. These systems are particularly useful for maintaining the uniformity of materials which contain fillers, ensuring a consistent and reliable dispensing process.

Features & Benefits

- Allows dispensing from bulk, bottles or other containers

- Clear glass cylinder enables visual gauge of material levels inside

- Max working pressure 60 psi/4 bar

- Integral safety pressure release valve

- Disposable material paths for ease of use and reduced maintenance

- Suitable for a wide range of lower viscosity liquids

- Electric agitation versions maintain uniformity of materials which contain fillers

- May also be used as a degassing tank

Specifications

| Model | Max working pressure (psi/bar) | Air Inlet | Air Outlet | Capacity (L) | Weight (kg) | Inner / outer diameter (mm) | Overall height / width (mm) | Height without lid (mm) |

|---|---|---|---|---|---|---|---|---|

| IDMPPCTG-500ML | 60/4 | 1/4″ or 6mm quick-connect | 1/4″ or 6mm tubing (straight through) | 0.5 | 2.4 | 65 / 75 | 272 / 209 | 187 |

| IDMPPCTG-2000ML | 60/4 | 1/4″ or 6mm quick-connect | 1/4″ or 6mm tubing (straight through) | 2 | 6.0 | 150 / 160 | 248 /166 | 184 |

| IDMPPCTG-1000CL | 60/4 | 1/4″ or 6mm quick-connect | 1/4″ or 6mm tubing (straight through) | 10 | 7.5 | 190 / 200 | 465 / 206 | 384 |

| Model | Max working pressure (psi/bar) | Air Inlet | Air Outlet | Capacity (L) | Weight (kg) | Mixer speed min / max (rpm) | Torque (Nm) | Inner Diameter (mm) | Overall Height (mm) |

|---|---|---|---|---|---|---|---|---|---|

| IDMPPCTGEL-2000ML | 60/4 | 1/4″ or 6mm quick-connect | 1/4″ or 6mm tubing (straight through) | 2 | 7.0 | 40 / 800 | 1.4 | 150 | 285 |

| IDMPPCTGEL-1000CL | 60/4 | 1/4″ or 6mm quick-connect | 1/4″ or 6mm tubing (straight through) | 10 | 8.1 | 40 / 800 | 1.4 | 150 | 485 |

Directions for Use

- Ensure you are wearing correct PPE. Consult with the safety data sheet for your material.

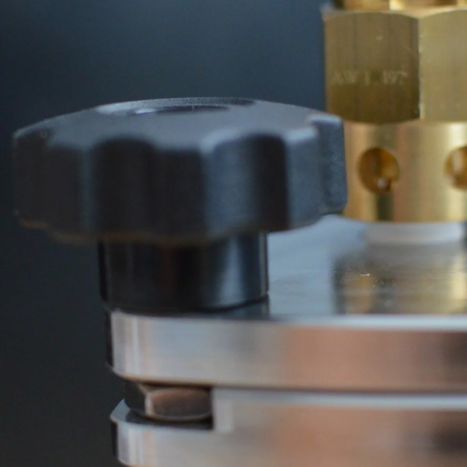

- Remove the threaded thumbscrews and lift off the reservoir’s lid.

- Place an open bottle of liquid in the centre of the reservoir.

- Return the lid to the top of the reservoir whilst assuring that the dip tube is positioned inside the bottle of liquid.

- Tighten thumbscrews evenly.

- Ensure the regulator is fully closed before connecting the air line.

- Connect all material and air lines supplying pressure to the reservoir.

- Slowly increase pressure by gently opening the regulator until desired material flow is reached.

- Don’t forget to depressurise the pot after use by gently loosening the air release valve.

Ordering Information

| Part number | Description |

|---|---|

| IDMPPCTG-500ML | Pressure pot – 0.5 litre capacity |

| IDMPPCTG-2000ML | Pressure pot – 2 litre capacity |

| IDMPPCTG-1000CL | Pressure pot – 10 litre capacity |

| IDMPPCTGEL-2000ML | Pressure pot – 2 litre capacity with electric agitation |

| IDMPPCTGEL-1000CL | Pressure pot – 10 litre capacity with electric agitation |

Let’s start by talking about your application

- Last updated: March 2024

- Version: 5.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.