Optical Adhesives & Encapsulants from Polytec PT

About Polytec PT Optical Adhesives & Encapsulants

Polytec PT offers a range of high performance optical adhesives for use in optical and medical applications. The materials are either optically clear or black opaque.

Features & Benefits

- Products with high clarity and excellent optical transmission

- Medically approved – ISO 10993

- Flexible epoxy systems

- Resistance to autoclaving and steam sterilisation

- Process convenient packaging, including twin-packs and premixed and frozen syringes

- Application specific formulations

Applications

- Medical device manufacture – USP Class VI

- Opto-electronics

- Hybrid microelectronics

- Optics

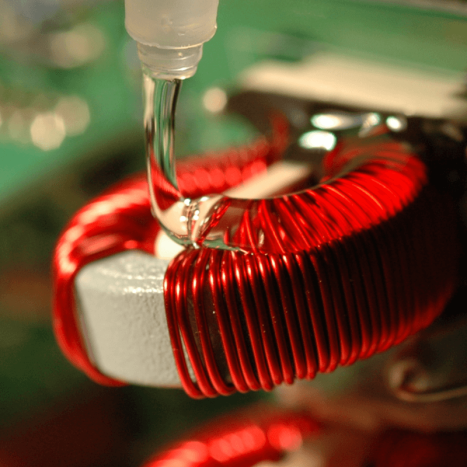

- Fibre optics

- Bonding

- Encapsulation

- Impregnation

- Underfill

Selector Guide

| Part number | Features | Applications |

|---|---|---|

| Polytec EP 610-2 | · Number of components: 2 · Mix ratio by weight: 100:50 · Temperature range: -55 to +150°C · Consistency: flowable liquid · Colour: translucent · Shore hardness: A65 |

Polytec EP 610-2 is used for stress-free bonding of large optical components with different CTEs. This material is suggested for applications in the optics, fibre optics, opto-electronics, medical and semiconductor technology.

EP 610-1 is also available in a thixotropic and non-flowing version. All are available pre-mixed, frozen and bubble-free. |

| Polytec EP 655 | · Number of components: 2 · Mix ratio by weight: 100:10 · Temperature range: -55 to +220°C · Consistency: flowable liquid · Colour: yellow/amber · Shore hardness: D80 |

Polytec EP 655 provides extreme temperature, chemical, electrical and moisture resistance. It was designed for medical, semiconductor, hybrid, piezo and fibre optic applications. It has excellent adhesion to glass, metal, ceramics, ferrite and most plastics. Recommended as an adhesive, impregnation and encapsulation. Its tough-elastic properties allow assemblies and potting of substrates with dissimilar coefficients of thermal expansion. Polytec EP 655 has passed more than 100 autoclave steam cycles. |

| Polytec EP 660 | · Number of components: 2 · Mix ratio by weight: 100:17 · Temperature range: -55 to +240°C · Consistency: flowable liquid · Colour: light yellow · Shore hardness: D85 |

Polytec EP 660 is a 100% solid, two-component, low viscosity epoxy impregnation and coating material. It has an excellent chemical and moisture resistance and can withstand operating temperature up to 300°C. It is recommended as sealant and impregnation for all soaking surfaces like ceramic, wood, plastics, high temperature fabric and powder as well as fibre bundles. A typical application is the impregnation and sealing of the magnesium oxide filler in tubular heaters / heating elements. |

Other Information

|

Adhesive Problem? What’s the Cure?

A guide to adhesive bonding, considering structural bonding and the criteria involved for successful assembly. |

- Last updated: November 2022

- Version: 4.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.