When gas sensor manufacturer DD-Scientific wanted to improve the accuracy, repeatability, and productivity of an epoxy sealing process, they asked us. DD-Scientific now benefits from robot-mounted preeflow® eco-DUO precision metering, mixing and dispensing systems, which save the company 23 days of staff time per year, while maintaining the high-quality the company’s products demand.

DD-Scientific’s sensors are used in many different applications, from industrial gas safety to carbon monoxide detectors for the home. Recently, the company has invested heavily in technology to ensure it is working productively and efficiently, while delivering high quality sensors. The company wanted to automate an epoxy sealing process — a vital step that prevents its sensors from leaking. The process was previously done by a team of staff, who mixed and applied the two-part material manually.

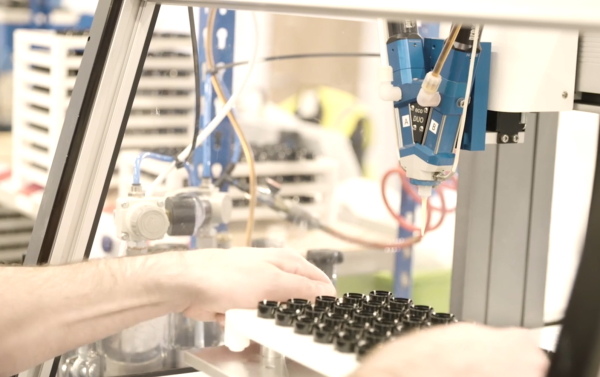

The company got in touch with Intertronics, who supplied the preeflow eco-DUO integrated with a Fisnar dispensing robot. This volumetric dispensing system uses the precision dispensing of the preeflow eco-PEN, by integrating two eco-PENs through a manifold and a static mixing nozzle. It provides extremely precise metering, mixing and dispensing of critical two-part materials, offering accuracy of ±1%, >99% of the time. Automating the sealing process means they dispense the right amount of epoxy, in the same place, every time — achieving the highest levels of quality.

“A key selling point of our gas sensors is that they will not leak during their lifetime,” said Rob White, Sales Director at DD-Scientific. “We take pride in supplying our customers with the absolute best equipment, to support them with their life-saving technology, be it a carbon monoxide sensor on an incubator for a newborn baby or in someone’s home.

“With a throughput of 1.5 million sensors a year, all with a minimum of two pins to seal, the time saved by removing the manual processes equates to 23 days a year,” added White. “We have been able to move the five people involved in the manual process into more valuable areas of the business and can now produce a potentially life-saving gas sensor every seven seconds.”

“There is a real buzz in the air at DD-Scientific,” said Matt Baseley, one of our talented Technical Sales Executives. “The team is clearly committed to being the best in their field. Equipped with an automated, volumetric dispensing process, DD-Scientific can maintain its clear competitive advantage and increase its throughput, all while making time and resource savings. We love that they have called our system ‘Barbara’, and made a movie about her! I’m excited to see what the company does next.”

Categories: case study, dispensing, electronics, epoxies, mixing, productivity, robotics, sealants