Precision Microdispensing Jetting Valve for Low to Medium Viscosity Materials

Vermes MDS 3050+

About Precision Microdispensing Jetting Valve for Low to Medium Viscosity Materials

The VERMES MDS 3050+ microdispensing jetting valve systems is a jetting valve for the precision dispensing of material in small volumes at fast speeds with extremely high accuracy and repeatability. The rising miniaturisation of individual components in production processes demand smaller beads and lines for dispensing whilst increasing production throughput, process reliability and consistent repeatability.

Based on piezoelectric fluid jetting technology, the VERMES MDS 3050+ grants contactless application of materials at high speed with precision at a faster dispensing rate than those of pneumatic valve technologies.

The VERMES MDS 3050+ will easily dispense materials up to 8000 mPas in repeatable single dots or beads of ≥5 nl. Example fluids include underfillers, glues, hot melts, silicones, solder fluxes, oils and greases. These materials can be supplied to the valve via a choice of media such as 3ml to 55ml cartridges or pressure pot and hose interface.

For the dispensing of very high viscosity materials, please see the VERMES MDS 3200+.

Specific to production requirements, components of the valves including tappets, nozzles and heating options can be customised to optimise the dispensing process of your application.

Features & Benefits

- Suitable for low to medium (up to 8,000mPas) viscosity materials

- Reduced production times and increased throughput as a result of fast speeds: frequency >3,000Hz

- Multiple customisable configurations using interchangeable parts such as nozzle heating

- Dispense failure or stoppages are trackable with built in real time in the MDC 3090+ controller

- Easy cleaning process reduces downtime of equipment

Applications

Some examples of applications that could benefit from using a micro dispensing valve system include:

- Life sciences, medical diagnostics and pharmaceutical

- Water based cell and protein solutions

- Electronics, semiconductors

- Conductive adhesives

- Flip chip advanced packaging

- Watch manufacturing and precision mechanics

- Synthetic oils, greases, adhesives

- Bearing and shaft journals

- Renewable energy

- Solder paste, edge/frame sealing, coatings, grease

- Research & Universities

- Data tracking

- RFID tags, antennas

- Automotive

- Anaerobic adhesives

- Sensors, electronic drives

- Consumer electronics

- Optical display adhesives, hot melt materials

- Mobile phones, flat-panel display and printer production

- Lighting and Optoelectronics

- Silicones

- LED production

Specifications

| Specification | VERMES MDS 3050+ |

|---|---|

| Dispensing viscosity | up to 8,000 mPas |

| Dimensions | 103 mm H x 39.5 mm W x 10 mm D |

| Minimum dispensing quantity | 5 nl per pulse (depending on medium) |

| Minimum droplet diameter | 150 μm (depending on medium) |

| Supply pressure | 0.1 – 8 bar (rel.) maximum: 30 bar |

| Maximum frequency | >3,000 Hz |

| Optional heating system | Regulated nozzle heating: 180°C, higher upon request |

Controller

The VERMES MDS 3020+ micro dispensing valve system includes the valve and corresponding controller, the VERMES MDC 3090+.

MDC 3090+ Controller

|

|

| Specification | MDC 3090+ Controller |

|---|---|

| Dimensions | 128 mm H x 102 mm W x 173 mm D |

| Power connection | 110/240 V AC, 50/60 Hz power socket (back side) |

| Memory for parameter sets | Internal: 10; External: unlimited |

| Valve operating modes | Burst Mode: predefined burst after trigger signal Single Shot Mode: path length dependent triggering Infinite Mode: number of shots controlled by external trigger External Mode: application controlled definable drop volume setting |

Other Information

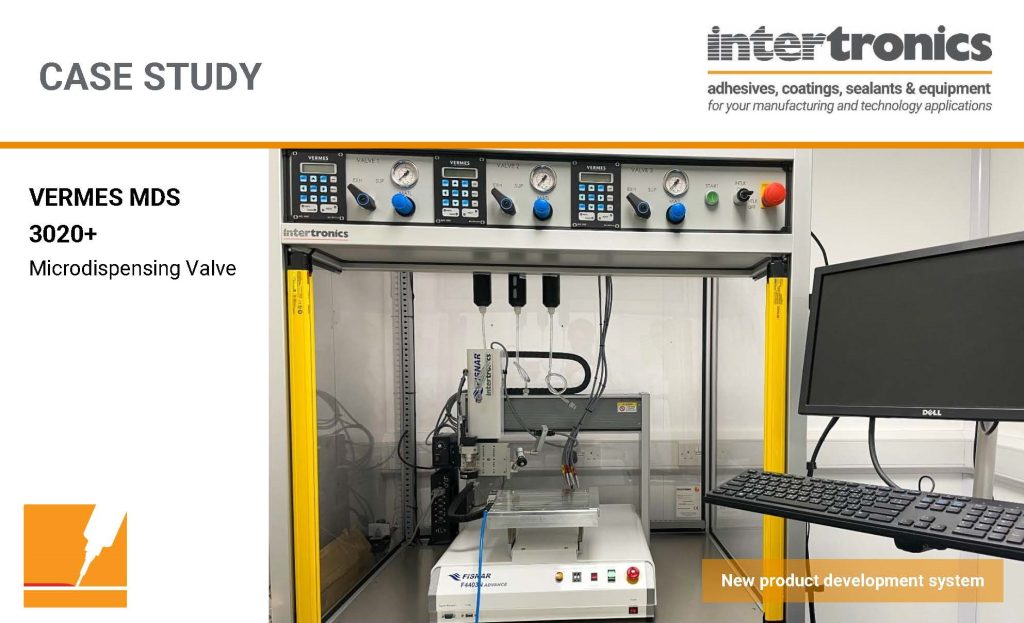

See how the jetting valves work as part of a real application in these robotics Case Studies:

|

Improving accuracy, repeatability, and speed using jet dispensing

By automating production processes and upgrading their dispensing technology to a microdispensing jetting valve, water analysis technologies manufacturer, Palintest, improved their accuracy, repeatability and more than doubled throughput. |

Ordering Information

| Part number | Description |

|---|---|

| MDS 3050 microdispensing valve system including MDV 3050 Valve and MDC 3290+ Controller | |

| MDV 3050 Valve | |

| MDC 3290+ Controller |

Next Steps

Our technical sales team are on hand to discuss your application requirements. Click here to get in touch.

Find out more information on how to purchase.

- Last updated: October 2022

- Version: 1.0

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.