Fast UV Curing, Form-in-Place Gaskets from Dymax

About Fast UV Curing, Form-in-Place Gaskets from Dymax

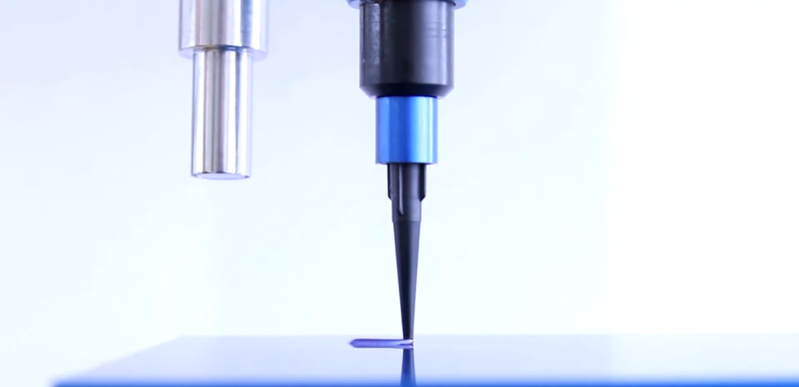

Dymax UV Curing Form-In-Place (FIP) and Cure-In-Place (CIP) Gaskets cure completely in seconds – even to 6mm thick beads – with good compression set. UV/Visible light curing, FIP/CIP gaskets eliminate ovens, racking, stacking, and waiting for traditional FIP/CIP gaskets to cure. Designed for sealing intricate, complex configurations as well as flat surfaces or wide, shallow grooves, permanent FIP/CIP gaskets can eliminate the delay experienced with slow-curing resins and the design and inventory expense associated with pre-cut gaskets.

Dymax gaskets can easily accommodate component design changes and part variation without additional development costs. Dymax Form-In-Place/Cure-In-Place gaskets are ideal for trim assembly, sound and vibration dampening, and non-skid applications and have been used to replace RTV silicone gaskets, resulting in speedier production, improved product yield, and reduced labour used to shuffle parts.

Selector Guide

| Adhesive | Applications | Features |

|---|---|---|

| Dymax GA-103 | Formulated for fuel cells, underwater enclosures, and high temperature sealing applications which require low compression set | UV/Visible light curing; excellent water resistance; excellent acid/base resistance; self-levelling gasket resin; high and low temperature resistant; low compression set; silicone free; conforms to intricate and complex component configurations |

| Dymax GA-108 | Formulated for electrical closures, HVAC ductwork, appliance casings, speaker assembly, and automotive moisture sealing closures | UV/Visible light curing; soft, tacky gasket; low compression set; flexible gasket; good adhesion to wide variety of plastics, metals, glass, and ceramics; silicone free; black in appearance; conforms to intricate and complex component configurations |

| Dymax GA-112 | Formulated for appliance housings, critical electronic assemblies and devices, and electrical conduit boxes | UV/Visible light curing; cures in seconds; silicone free; excellent tear resistance; cures soft and tack free; low outgassing; moisture-resistant sealing; conforms to intricate and complex component configurations |

| Dymax GA-120 | Formulated for speaker assembly, sound dampening, and automotive enclosures | UV/Visible light curing; soft, low-durometer tacky resin; self-levelling viscosity; good deflection; adheres to a wide variety of plastics, metals, glass, and ceramics including glass-filled nylon; silicone free; conforms to intricate and complex component configurations |

| Dymax GA-140 Dymax GA-140-B Dymax GA-140-LV Dymax GA-140-SC Dymax GA-140-UR |

Formulated for fuel cells, automotive door handles, appliance housings, and critical electronic assemblies and devices | UV/Visible light curing; moisture and chemical resistant; tack free; low outgassing; soft gasket material with high adhesion to plastics while providing a barrier to prevent absorption or penetration of air, dust, moisture, liquids, and gaseous substances; cures in seconds; silicone free; conforms to intricate and complex component configurations; excellent tear resistance for serviceable and limited-service applications; See-Cure (DYMAX GA-140-SC) and Ultra-Red (DYMAX GA-140-UR) grades available |

| Dymax GA-142 | Formulated for electrical enclosures, HVAC ductwork, automotive enclosures, appliance casings, automotive door handles, and speaker assembly applications | UV/Visible light curing; good adhesion to nylon and metals; soft, tacky gasket; silicone free; cures in seconds; conforms to intricate and complex component configurations; adheres to a wide variety of plastics, metals, and nylon 6/6 |

| Dymax GA-145 | Formulated for fuel cells, automotive door handles, appliance housings, and critical electronic assemblies and devices | UV/Visible light curing; low outgassing; cures soft and tack free; excellent tear resistance; black translucent in appearance; cures in seconds; silicone free; conforms to intricate channels or recesses |

| Dymax GA-201 | Formulated for sealing plastic, glass, and metal surfaces and enclosures as well as sealing plated surfaces | UV/Visible light cure; tack-free after proper cure; moisture and chemical resistance; soft and durable after proper cure; colourless in appearance; silicone free; conforms to intricate channels and recesses |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

Our Technical Bulletins page has links to:

- Technical Bulletin: FIP Gaskets Cheaper Than You Think

- Last updated: November 2022

- Version: 4.5

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.