PiezoBrush PZ3 Handheld Plasma Surface Treatment

About PiezoBrush PZ3 Handheld Plasma Surface Treatment

Also available to buy online at ![]()

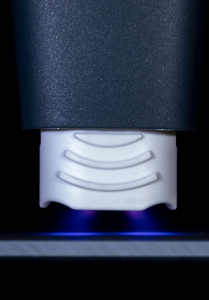

The PiezoBrush PZ3 is one of the world’s smallest, highly effective handheld plasma treatment device.

Plasma surface treatment can improve adhesion, wetting, and cleanliness of surfaces. The PiezoBrush PZ3 introduces the benefits of plasma surface treatment into a convenient and lightweight handheld format. Using Piezoelectric Direct Discharge (PDD®) Technology, which has been specially developed by Relyon Plasma, the device transforms low input voltage into high electric field strengths, dissociating and ionizing the ambient gas (normally air).

Requiring no specialist technical knowledge to operate, the PiezoBrush PZ3 is equipped with several built-in process control features which can be adjusted through its simple user interface, allowing users to tailor the unit to suit their applications. Building upon the previous generation of PiezoBrush, the PZ3 can be programmed to deliver accurate and repeatable treatment processes though its timer, which includes stopwatch, countdown, and metronome modes.

The PiezoBrush PZ3, which requires no additional gas supply, and generates cold-active plasma at a temperature of less than 50°C, meaning that it can be used to treat temperature-sensitive substrates.

PiezoBrush PZ3-i Plasma Surface Treatment Tool for Automation

For manufacturers looking for a robot mountable plasma surface treatment tool which is capable of semi-automated or automated processes, the PZ3-i combines the effectiveness of plasma surface activation with the improved productivity and repeatability of using a robot to automate a process.

Features & Benefits

- Simple, safe and intuitive

- Surface treatment of plastics, glass, ceramics, metals, semiconductors, natural fibres and composite materials

- Improves adhesion & wetting of surfaces

- Activation and functionalisation of the surfaces of various materials

- Optimisation of bonding, painting, printing and coating processes

- Ultra-fine cleaning and odour reduction

- Efficient and environmentally friendly – no chemicals

- Uses “cold plasma” to enable treatment of temperature-sensitive substrates

- Convenient and lightweight handheld design

- Process control for repeatable treatments

- Interchangeable modules for optimised treatment on different substrates

Applications

The PiezoBrush PZ3 is suitable for use in manual or semi-automated production, new product development, and in research and development settings such as a laboratories.

- Joining and bonding projects

- Development and optimisation of production processes

- Research facilities and laboratories

- Microbiology, microfluidics and food technology

- Medical and dental technology

- Prototype and architectural model making, 3D printed parts

- Medical

Filters, cell wells, test tubes, catheters, syringes, petri-dishes, needle hubs, lenses

Filters, cell wells, test tubes, catheters, syringes, petri-dishes, needle hubs, lenses - Automotive

Fuse covers, engine parts, air bag covers, rubber profiles, tubing, headlights - Electronics

Cable, switches, polyester pcb’s, housings & enclosures, screens - Consumer

Irons, blenders, shakers, measuring containers - Food, cosmetics & drug

Bottles, caps, jars, tubes - Professional model making

Preparing materials such as glass, GRP, ABS and other synthetic materials for bonding

The PiezoBrush allows simple germ reduction on a great variety of surfaces such as glass, plastics or metals and thus provides excellent support in effecting processes in the field of microbiology, medicine, microfluidics or food engineering.

Specifications

| Specification | |

|---|---|

| Typical treatment speed | 10 – 50 mm/s |

| Typical treatment distance | 2 – 5 mm |

| Typical treatment width | 5 – 29 mm (compressed air), up to 50 mm (nitrogen), modularly expandable |

| Plasma gas temperature | < 50 °C |

| Modules | Standard and nearfield |

| Activation efficiency | 65 m2/kWh |

| Process gas | 5 – 20 mm |

| Dimensions (mm) | 36 x 228 x 51 |

| Electrical connection | 15V DC |

| Weight | 180g |

Modules

In order to achieve optimised surface activation for different substrates, the PiezoBrush PZ3 has been equipped with four interchangeable modules.

The device detects which module is installed and automatically adjusts the parameters accordingly.

|

Standard module

This module is designed for the surface treatment of non-conductive substrates such as plastics, ceramics or glass. For effective treatment, a module-to-substrate distance of 1 to 5 mm is recommended. If uncontrolled arcing occurs on the substrate during use, the device switches off automatically. In this case the surface is at least partially conductive and should therefore be treated with the Nearfield module. |

|

Nearfield module

This module is used to treat electrically or partially electrically conductive materials such as metals, CFRP, indium tin oxide or conductive plastics. However, this module may also be necessary for the ideal treatment of materials with conductive coatings or assemblies with conductive components. With this module, the plasma only ignites when it is close enough to a conductive surface (this may also be hidden under a thin insulating layer). At a distance of a few millimetres, a violet glow is visible in the gap between module and substrate indicating that the treatment is being performed. |

|

Needle module

The Module Needle is suitable for treating small or hard-to-reach areas in non-conductive materials. It can be used to treat narrow grooves, bores or other cavities, as very fine processing is performed with the needle. |

|

Multigas module

This module can be operated with the inert gases nitrogen, argon or helium to improve surface activation of difficult-to-bond substrates, such as PTFE. It is used in combination with a silicone hose, which is plugged onto the gas connection. |

|

Nearfield Needle module

The Module Needle is suitable for treating small or hard-to-reach areas in conductive substrates such as CFRP, indium tin oxide or conductive plastics. It can be used to treat narrow grooves, bores or other cavities, as very fine processing is performed with the needle. |

Display

For process control of plasma treatment, the PiezoBrush PZ3 is equipped with various features that can be selected and modified via the user friendly display.

- Process control

◊ Stopwatch: for monitoring the treatment time

◊ Countdown: set treatment time with automatic switch-off

◊ Metronome: acoustic signal after a defined treatment time - Power adjustment: reduction of plasma power in several increments

Other Information

Find out more about the technology behind the PZ3 by reading our technical bulletins and white papers:

- PiezoBrush PZ3 Operation Principle and Characteristics

- Cold Plasma in the Electronics Industry

- Plasma Technology for Surface Cleaning

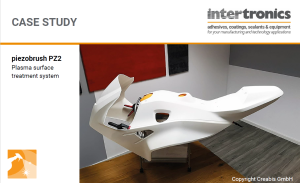

See how the PiezoBrush works as part of a real application in this plasma surface treatment Case Study:

|

Increasing the strength of bondlines in 3D printed assemblies threefold

A significant challenge for Creabis GmbH, a 3D printing service provider, is the 3D printing of large and complex components, as normally 3D printers have maximum component dimensions of ~600mm. To make use of the advantages of 3D printing for larger components, they are printed as individual parts and then bonded together. Plasma surface treatment greatly enhances the strength of the bonds on these 3D-printed assemblies. |

|

Improving overmoulding adhesion with plasma treatment

Wavecon LTD, a provider of subsea cable assemblies, required a method of pre-treating their difficult-to-bond substrates prior to encapsulation and overmoulding processes. Seeking a more efficient and consistent process than painting substrates with liquid primers, the manufacturer chose to use the PiezoBrush PZ3. |

All Downloads

Ordering Information

Let’s start by talking about your application

- Last updated: January 2024

- Version: 2.1

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.