Opti-tec 7020 Optically Clear Silicone Potting Compound

About Opti-tec 7020 Optically Clear Silicone Potting Compound

Also available to buy online at ![]()

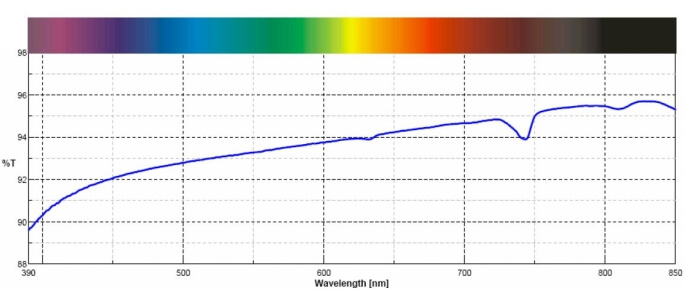

Opti-tec™ 7020 Optically Clear Silicone Rubber Potting Compound is a two-part, clear liquid silicone elastomer which will cure at room temperature or can be accelerated at elevated temperatures. It has a low viscosity, which allows for ease of flow around complex parts, providing electrical insulation and shock resistance. Its combination of transparency, non-yellowing and compliance makes it suitable for encapsulation of sensitive electronic or opto-electronic parts (e.g. LEDs), protecting the components from vibration, moisture and atmospheric contaminants.

Features & Benefits

- Optically clear

- Compliant

- Room or low temperature cure

- Non-yellowing catalyst system

- Low shrinkage

- Excellent for protecting LEDs and solar applications

- Convenient 10:1 mixing ratio for use in automatic dispensing equipment or hand mixing

- Low viscosity which allows for ease of flow around complex parts, providing electrical insulation and shock resistance

- Contains no solvents

- Has a chemical composition which provides hydrolytic stability and reversion resistance. It is an addition cure silicone with a platinum catalyst.

Applications

- Optical assembly

- Opto-electronics, photonics, LEDs

- Optical encapsulation & glob topping, casting, potting

- Solar panels

- Electronics potting

Specifications

| Specification | Mixed | Resin | Hardener |

|---|---|---|---|

| Colour | Clear; colourless | Clear | Clear |

| Viscosity (mPa.s) | Easily pourable | 4000 | 500 |

| Specific gravity | 1.02 | 1.01 | |

| Mix ratio | 10:1 | ||

| Pot life (@ 23°C) | 4 hours | ||

| Cure schedule (approx maximum time) | 25°C – 20 hours | ||

| 100°C – 60 mins | |||

| Cured properties (60 minutes @ 100°C) | |||

| Shore Hardness | A40 | ||

| Temperature range | -60 to 200°C | ||

| Tensile strength | 4.8 MPa | ||

| Elongation at break | 100% | ||

| Linear shrinkage | < 0.1% | ||

| CTE | 275 ppm/°C | ||

| Dielectric strength | 20 kV/mm | ||

| Dielectric constant | 2.69 @ 1000Hz | ||

| Dissipation factor | 0.0006 @ 1000Hz | ||

| Volume resistivity | 1.7 x 1015 ohm-cm | ||

| Thermal conductivity | 0.18 W/m K | ||

| Specific heat | 1.255 kJ/kg | ||

| Refractive index | 1.405 | ||

| Transmittance | 90.3% |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Instructions

Opti-tec 7020 is available in twinpacks or in bulk.

For bulk, weigh 10 parts of Part A to 1 part of Part B. Allowable tolerance on the measured weight for either Part A or Part B is +/-2.5%. The mixing container should be 4 to 5 times larger than the volume of silicone. Use stainless steel, HDPE, polypropylene, etc. Using clean tools, thoroughly mix the A and B components.

The twinpack sachet is a clear film sachet, with the resin and hardener separated by a removable clip and rail divider. Click here for twinpack mixing instructions.

Care should be taken to avoid excessive aeration. For many applications, natural degassing will be sufficient. If degassing is required, intermittently evacuate at 20-40 mbar for 15-30 minutes. Leave for a few minutes after releasing the vacuum to allow surface bubbles to collapse.

Cure begins as soon as the components are mixed in the recommended ratio. Complete cure is normally achieved in 16 to 24 hours at ambient temperatures of 20-30°C. Cure can be accelerated by heating to 50-120°C.

Ordering Information

Opti-tec 7020 is supplied in matched kits in a 10 to 1 ratio of Part A to Part B – standard size is 1.1kg total. Alternatively, Opti-tec 7020 is supplied in pre-weighed 250 gram twinpacks.

| Part number | Description |

|---|---|

| OPT7020-1.1KG |

Optically Clear Silicone Potting Compound – 1.1 kilogram kit |

| OPT7020-250G |

Optically Clear Silicone Potting Compound – 250 gram twinpack |

Keep the product in clearly labelled containers.

Let’s start by talking about your application

- Last updated: January 2024

- Version: 6.7

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.