Fast, UV Cure Conformal Coatings from Dymax

About Fast, UV Cure Conformal Coatings from Dymax

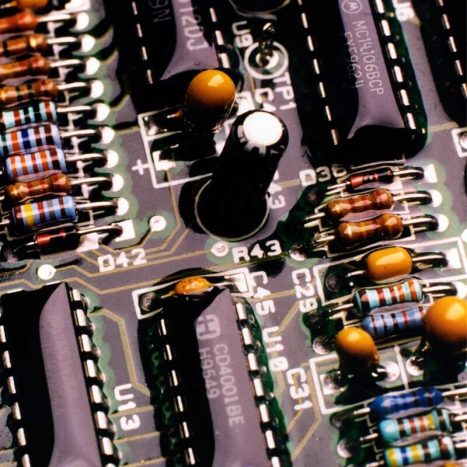

Dymax UV Cure Conformal Coatings cure tack-free in seconds upon exposure to UV/visible light to help streamline manufacturing assembly processes. Apply, cure, and ship immediately and eliminate the time-consuming steps of traditional thermal-cure and room temperature-cure conformal coatings. These 100% solvent-free conformal coatings can be applied over the entire surface of a printed circuit board or in selective areas to provide complete protection from harsh environments. Dymax conformal coatings are available for tin whisker mitigation, humid environments, and shadowed areas.

Rigid and flexible coatings are electrically insulating, have high ionic purity and excellent environmental resistance. They exhibit low stress under thermal cycling and adhere well to flex circuit substrates. IPC, MIL Spec I-46058C and UL approved grades, multiple viscosities and ultra fluorescing and black grades are available. Flexible coating for medical electronics passes ISO 10993 testing.

Solvent-free conformal coatings contain low VOCs, eliminating the need for solvent handling, while enhancing worker safety and minimising environmental impact. Each conformal coating is one part (no mixing required) for easy dispensing.

Features & Benefits

- Cure in seconds with UV/visible light

- Single part, solvent free

- No mixing required and easy to apply

- Secondary heat or moisture cure for printed circuit boards with shadowed areas

- IPC, MIL SPEC, ISO 10993 and UL 94 V-0 approvals

- Low outgassing – meets ASTM E595

- Certified to meet Mil-Std 833 Method 5011

- Halogen-free

- Multiple viscosities

- Rigid and flexible versions

- Clear, fluorescing, and black-coloured coatings

Specifications

| Product | Application | Features |

|---|---|---|

| Dymax 9-20557 | Forms tough, clear circuit encapsulant upon exposure to longwave UV/visible light; excellent for encapsulating, potting, sealing and bonding | Flexible; resists yellowing, vibration, impact and thermal shock; excellent adhesion to most soldermasks/resists and pcb materials; fluorescing; secondary heat cure capability; recommended for use with no-clean solder flux |

| Thin, flexible conformal coatings | Solvent free; fast light cure; secondary heat cure; low viscosity is compatible with most types of spray equipment; low modulus for thermal excursions enhances thermal shock performance; isocyanate free; IPC-CC-830 approved and MIL-I-46058 listed | |

| Dymax 9451 | Thin protective black coating; true black material specially formulated to cure with heat in applications where shadowed areas exist; excellent for hiding components and pcb features | UV/Visible light cure in seconds; secondary heat cure for shadowed areas; true black conformal coating; designed for thin coatings; one-part coating – no mixing required; UL 94 V-0 flammability certified |

| Dymax 9483 | Thin, tack free, conformal coating for control modules, automotive sensors and components | Solvent free; fast light cure; secondary moisture cure over time; moisture cure provides room temperature cure for coating entrapped in shadowed areas; thermal cycling properties; corrosion resistant; blue fluorescing; meets Military Specification MIL-I-46058 |

| Dymax 9452-FC | Thin conformal coating, film coating, flow coating dispensing | UV/visible light cure; secondary heat cure for curing shadowed areas; LED curable; blue fluorescing; very good thermal shock resistance; excellent wettability; 100% solids |

| Dymax 984-LVUF | Highly fluorescing for easy inspection; for densely populated circuit boards requiring shadow cure | Hard; clear; fluorescing; environmentally resistant; tack-free surface; IPC, UL and MIL Spec approved; moderately low viscosity; cures by UV light and secondarily with heat |

| Dymax 1901-M | Coating for medical electronics, sealing, moisture barrier. Adheres to glass, FR-4, metal, ceramic, glass-filled epoxy, CAP, PS, TPU and Al | Can be cured with LED UV curing lamps; flame retardant; solvent free; repairable; suitable for both flexible and rigid substrates; ISO 10993 tested |

| New | ||

| Dymax 9771 | Dual cure with both UV/visible light and moisture to reach shadow areas. Low outgassing conformal coating, meets MIL-STD 883 Method 5011 standards for missiles, satellite, and space applications that are exposed to extreme conditions | NASA low outgassing conformal coating is MIL-Std 883 Method 5011 certified, meets ASTM E595 TML and CVCM, UL 94 V0, UL 746E, MIL-I-46058C listed (pending), IPC-CC-830-B approved (pending) and in full compliance with the RoHS2 Directives 2015/863/EU |

| Safety Data Sheets |

|---|

| For the latest SDS for this product, please e-mail msds@intertronics.co.uk |

Other Information

See our Technical Articles & White Papers page for a link to Conformal Coating Made Easy.

- Last updated: November 2022

- Version: 12.2

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.