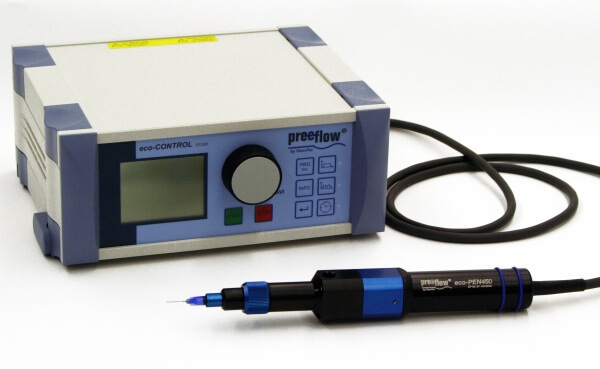

We recently introduced the preeflow® eco-PEN 450 from ViscoTec, which not only offers a greater capacity for high accuracy and highly repeatable volumetric dispensing – it also addresses the needs of a wide range of low to medium viscosity applications. These include oils and fats, colour mixes, silicones, sealing compounds, adhesives and even abrasive media, which can be easily handled by the innovative precision rotor-stator mechanism which we call an “endless piston”.

The eco-PEN 450 deals easily with dots and beads as small as 0.004 ml at up to 6 ml per minute, featuring viscosity autonomous application at pressures from 16 to 20 bar via luer lock dispensing nozzles or needles. Easy fitment to robotic or semi-automatic systems is facilitated by preeflow® EC200 controllers which are available in bench top or panel-mount format. The units are microprocessor controlled and simple to operate, without submenu, and with graphic support. External signals can be connected via I/O ports to a PLC for control in automated lines. A wide variety of dosing programs with part-management are storable. Error messages for filling level and motor current may also be monitored via an RS232 interface. Alternatively, for robotic and automated installations the preeflow® “plug-n-dose” Speed Control readily enables time/pressure control by external computer system.

The eco-PEN 450 is applicable to self-levelling low viscosity media and to non-self-levelling fluids with pressure feed.

Categories: adhesives, dispensing, medical